Heavy Lifting: The History of the Elevator Code

Heavy Lifting: The History of the Elevator Code

The use of cranes and other types of mechanical lifting equipment grew in step with the growth in freight railroading and shipping at the beginning of the twentieth century.

Guidelines for the safe design and operation of cranes were not yet in place, and the high incidence of injuries to dockworkers, railroad yardmen, and factory workers was of concern to a variety of organizations, including the Locomotive Crane Manufacturers Association and the Association of Iron and Steel Electrical Engineers, as well as to the U.S. Department of the Navy, and other government agencies, including the U.S. Department of Labor, which was formed in 1913. By 1920, these groups were pressing hard for worker protection and safety.

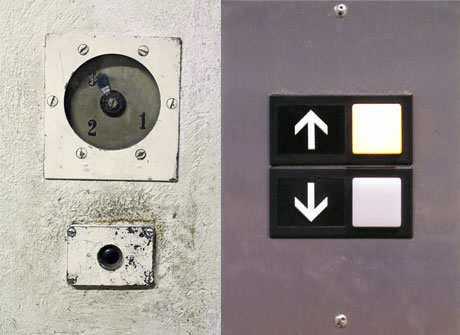

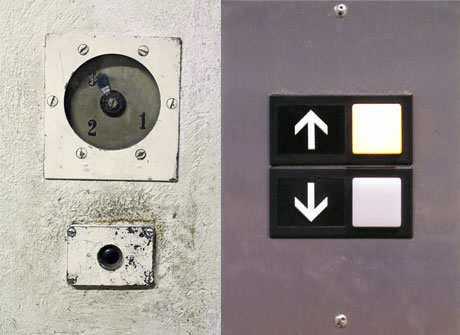

While the ASME Safety Code Correlating Committee was at work on crane safety in the years following World War I, a building boom was under way in America’s urban centers. As buildings became taller, the need for a device to move people and material goods to upper floors became apparent. Elevators already had been in service for several years, but the public was not entirely convinced of their safety. Although Elijah Otis invented a safety brake in 1853, which prevented the fall of the elevator platform in the event that its hoisting rope broke, the public generally feared elevators and were keenly aware of the need for safety.

As with boilers and cranes before ASME addressed them, little regulation and few design and operating guidelines existed to ensure safety in elevators. Code writing for elevators initially fell to the Elevator Manufacturers Association, then shifted to ASME in the post-war period. In 1921, ASME issued A17, Safety Code for Elevators, containing safety provisions for switches, door locking mechanisms, and speed.

A17, Safety Code for Elevators was a 25-page publication. Today’s ASME A17.1/CSA B44, Safety Code for Elevators and Escalators is a binational code, jointly developed by ASME and the Canadian Standards Association, contains more than 350 pages, and includes rules and guidelines for technologies that were not around ninety years ago, like relay control equipment and solid state computerized components. A key milestone in the development of the code occurred in 2007, when ASME, jointly with the Canadian Standards Association, published the first performance-based safety code, ASME A17.7/CSA B44.7.

[Adapted from “To Protect and Serve,” by John Varrasi, ASME Public Information, for Mechanical Engineering, July 2009.]

As with boilers and cranes before ASME addressed them, little regulation and few design and operating guidelines existed to ensure safety in elevators.