Microrobots Could Change How to Brush Teeth

Microrobots Could Change How to Brush Teeth

UPenn researchers working with nanoparticles developed microrobots that form bristles to brush teeth without help.

Brushing teeth is the most basic and common method of oral hygiene, taught to toddlers as soon as their teeth grow in. While toothbrushes have been electrified, and water piks help beneath the gums, the basic method of cleaning teeth has not changed for millenia.

That could change with the work of dental and engineering researchers who have developed a microrobot that cleans teeth. The hands-free system, while still in early development, has been effective in removing dental plaque and biofilm that contributes to tooth decay. Eventually, it could be a valuable tool for those without the dexterity or ability to clean their teeth.

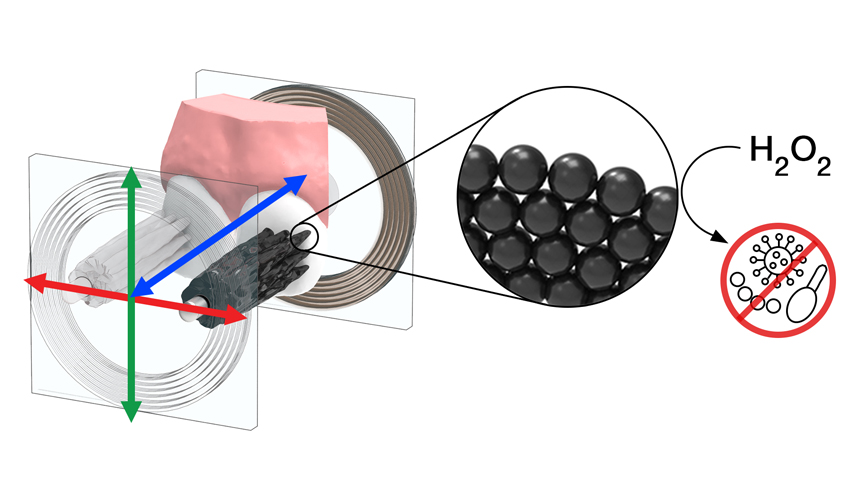

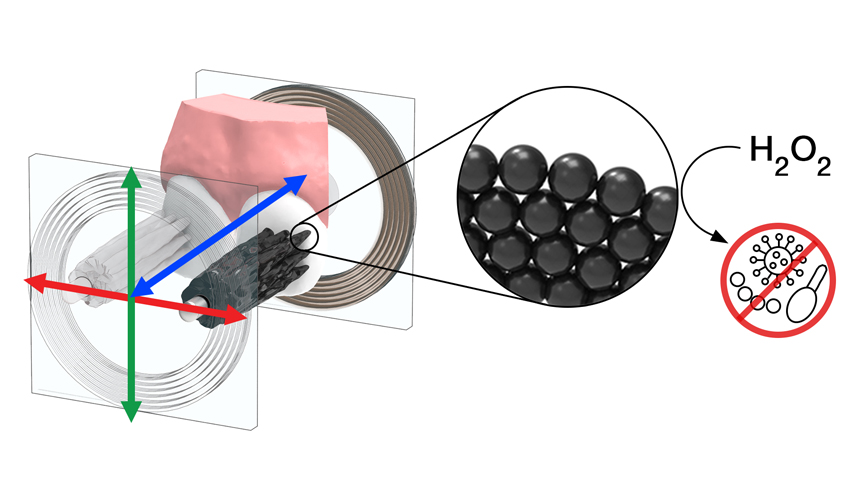

Developed at the University of Pennsylvania, the microrobots rely on iron oxide nanoparticles that have magnetic and catalytic properties. The particles can move and change configuration by using a magnetic field, actually forming bristle-like structures that remove bacteria and plaque from teeth.

Become a Member: How to Join ASME

Edward Steager, a senior research investigator at UPenn’s School of Engineering and Applied Science, had been working with iron oxide nanoparticles to move little magnetic robots in an attempt to manipulate single cells. Hyun Koo, a dentist and professor in the Department of Orthodontics at the university’s School of Dental Medicine, had been working with the same particles to improve dental health. A colleague introduced the two.

"We had been working with the same nanoparticles for completely different purposes,” Seager said. “There are two properties of these iron oxide nanoparticles that kind of come together to make them an interesting system for treating biofilms, and one of them is catalysis. They act like an enzyme to break down hydrogen peroxide, and I was completely unaware of this. It seemed to make a lot of sense to use both of these properties to explore biofilm removal both in a chemical and mechanical sense.”

The microrobots were first tested on small slabs of toothlike material, and then on 3D-printed tooth models based on scans to show the vagaries of the surface. For the third step, they were tested on real human teeth.

The researchers and their teams constructed a platform to electromagnetically control the microrobots, configuring them in different shapes. Two electromagnets are placed on either side of the teeth. When activated, the nanoparticles begin to grow in bundles and connect with each other in a very orderly way, Koo said. As they connect they also grow outward, forming a “bristle” that works to clean the teeth. They can be made strong enough to clean the teeth without damaging the gums.

More for You: Discovery of New Plasma-Enabled Process Offers Promise

Koo’s initial work on the nanoparticles became the foundation for the teeth-cleaning robots. It was not directly applicable to teeth, however, and it took the collaborators about two years to advance to the point where the microrobots performed properly. The results were published in 2022 in the journal ACS Nano.

The biggest challenge was the fact that we did all of the fundamental studies on a horizontal surface,” Koo said. “Now we are dealing with verticalized surfaces.” Repositioning the bristles to work on the vertical surface of teeth “took us a really long time to figure out,” he added.

You can imagine it is not particularly hard to kind of pull nanoparticles into a surface,” Steager said. "If you have a biofilm on the top of a surface and you pull from beneath, it is not particularly hard to get a nice attractive force to drag nanoparticles through the biofilm and disrupt it. If you turn that and have the biofilm on this [vertical] surface, how do you turn that geometry around? That was the biggest challenge.”

The team now is working to move the system from the lab to clinic, using mannequin heads to simulate the anatomy of the mouth and develop a device that can fit inside the mouth. In parallel, they are working with large animal models to advance the system within the geometric and anatomical constraints of the oral cavity, and clean both above and below the gum line, Koo said.

John Kosowatz is senior editor.

That could change with the work of dental and engineering researchers who have developed a microrobot that cleans teeth. The hands-free system, while still in early development, has been effective in removing dental plaque and biofilm that contributes to tooth decay. Eventually, it could be a valuable tool for those without the dexterity or ability to clean their teeth.

Developed at the University of Pennsylvania, the microrobots rely on iron oxide nanoparticles that have magnetic and catalytic properties. The particles can move and change configuration by using a magnetic field, actually forming bristle-like structures that remove bacteria and plaque from teeth.

Become a Member: How to Join ASME

Edward Steager, a senior research investigator at UPenn’s School of Engineering and Applied Science, had been working with iron oxide nanoparticles to move little magnetic robots in an attempt to manipulate single cells. Hyun Koo, a dentist and professor in the Department of Orthodontics at the university’s School of Dental Medicine, had been working with the same particles to improve dental health. A colleague introduced the two.

"We had been working with the same nanoparticles for completely different purposes,” Seager said. “There are two properties of these iron oxide nanoparticles that kind of come together to make them an interesting system for treating biofilms, and one of them is catalysis. They act like an enzyme to break down hydrogen peroxide, and I was completely unaware of this. It seemed to make a lot of sense to use both of these properties to explore biofilm removal both in a chemical and mechanical sense.”

The microrobots were first tested on small slabs of toothlike material, and then on 3D-printed tooth models based on scans to show the vagaries of the surface. For the third step, they were tested on real human teeth.

The researchers and their teams constructed a platform to electromagnetically control the microrobots, configuring them in different shapes. Two electromagnets are placed on either side of the teeth. When activated, the nanoparticles begin to grow in bundles and connect with each other in a very orderly way, Koo said. As they connect they also grow outward, forming a “bristle” that works to clean the teeth. They can be made strong enough to clean the teeth without damaging the gums.

More for You: Discovery of New Plasma-Enabled Process Offers Promise

Koo’s initial work on the nanoparticles became the foundation for the teeth-cleaning robots. It was not directly applicable to teeth, however, and it took the collaborators about two years to advance to the point where the microrobots performed properly. The results were published in 2022 in the journal ACS Nano.

The biggest challenge was the fact that we did all of the fundamental studies on a horizontal surface,” Koo said. “Now we are dealing with verticalized surfaces.” Repositioning the bristles to work on the vertical surface of teeth “took us a really long time to figure out,” he added.

You can imagine it is not particularly hard to kind of pull nanoparticles into a surface,” Steager said. "If you have a biofilm on the top of a surface and you pull from beneath, it is not particularly hard to get a nice attractive force to drag nanoparticles through the biofilm and disrupt it. If you turn that and have the biofilm on this [vertical] surface, how do you turn that geometry around? That was the biggest challenge.”

The team now is working to move the system from the lab to clinic, using mannequin heads to simulate the anatomy of the mouth and develop a device that can fit inside the mouth. In parallel, they are working with large animal models to advance the system within the geometric and anatomical constraints of the oral cavity, and clean both above and below the gum line, Koo said.

John Kosowatz is senior editor.