Frequently Asked Questions

General

- Identify the name and address of the ASME certified company which supplied the item in question,

- Identify the paragraph(s) in the governing Code/Standard which the complaint is based upon, and

- Provide objective evidence which supports the alleged nonconformance.

Scheduling

Finance

ASME's banking information can be found on the invoice. Please email ASME Conformity Assessment Department at ca@asme.org, if you have any questions.

Note: All payment methods should contain Account Number, Application Number and Invoice Number to ensure prompt processing of payment.

- By Wire Transfer: Please use the information on the invoice to submit payment via bank wire transfer.

- By Check: Please make checks payable to ASME and forward the check to ASME Accounts Receivable/Conformity Assessment, 150 Clove Road, Little Falls, NJ 07424-2100.

- By Credit Card: Please download the ASME Credit Card Form. Please upload the credit card form to ASME secure site Account Receivable. For additional information, send an email to ca@asme.org.

Payment Due: Payment is currently being processed. Please allow five to seven business days for funds to appear on the account. No further action is required at this time.

Review Onsite: Payment has been processed and your application is at the review/survey stage. No further financial action is required at this time.

Please provide the following information:

- Name of Bank

- Beneficiary Name

- Account Number / IBAN

- SWIFT (BIC) Code

- ABA Routing Number (if applicable)

Single Certification Mark

Introduction

ASME'/s product certification programs have grown dramatically. Starting with just two countries in the years prior to 1972, there are now 74 countries in which companies have been certified. ASME is proud that the value of these certification programs has been so widely acknowledged, and that ASME is playing this increasingly vital role in fostering product safety and international commerce.

The growth of these programs has presented many new opportunities, but also some challenges, especially regarding how to maintain the trademark registrations of ASME'/s 28 separate Certification Marks across the more than 100 nations in which these marks are currently used on products.

In order to streamline our multiple marking processes and more effectively manage our numerous global relationships, ASME is pleased to announce the introduction of a new single Certification Mark.

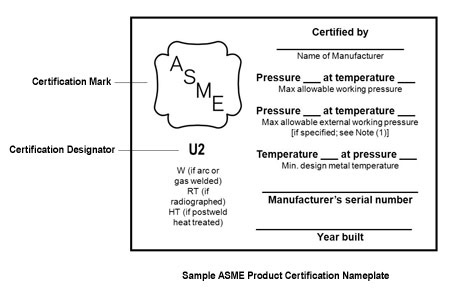

Instead of 28 separate Certification Marks, there will now be this single comprehensive mark. To maintain a link to the current marks, the new mark will be used in conjunction with a "Certification Designator" to indicate the applicability of the certification. The image shows an example of how the new mark would be used on a nameplate (in this case for a vessel constructed to Section VIII, Division 2).

Boiler and Pressure Vessel (BPV) Certification

No change in jurisdiction or AIA of Record

No change in upper management or quality control (QC) personnel affecting the company'/s quality control program

The distance involved is small enough (~100 miles)

Certificate Holders who are relocating within the same jurisdiction should contact the ASME Conformity Assessment Department at ca@asme.org if they wish to have an AIA audit conducted in place of an ASME Joint Review.

- The address of the new location, and distance from the previous shop location

- There are no changes in upper management or QC personnel affecting the company'/s quality control program

- There has been no change in the scope of manufacturing activities as currently listed in the scope on the ASME Certificate of Authorization

- That there is no major equipment change

- A summary of the audit conducted by the ASME designated organization at the new shop location to ensure that the Certificate Holder is implementing their quality control system as previously accepted at the last ASME review

- That the ASME designated organization has tested two pressure relief devices per test medium manufactured/assembled at the new shop location and the tested pressure relief devices have met the applicable requirements of the ASME Boiler and Pressure Vessel Code.

Note: For H (cast iron or cast aluminum) an ASME renewal review is required.

ASME will require written verification from both the ASME Team Leader who conducted the latest Joint Review, and the Certificate Holder'/s Authorized Inspection Agency (AIA), that the Certificate Holder'/s Quality Control (QC) manual and QC system have been revised to include all of the additional code requirements required to fabricate components for the requested Certificate(s) of Authorization. Upon receipt of a favorable recommendation from both the ASME Team Leader and the AIA as well as the receipt of applicable fees, ASME will issue the requested certificate(s).

The request from the Certificate Holder should include any applicable fees as shown in the renewal application package and be accompanied by: A description of the work to be completed, including the work/job number The number and type of code components involved (S, PP, H, U, etc.) The expected completion date for the work.

ASME will then contact the Certificate Holder'/s Authorized Inspection Agency (AIA) or ASME designee, as appropriate, and request:

- Written verification of the information provided by the Certificate Holder

- Verification that an audit of the Certificate Holder'/s shop facility has recently been performed and the AIA/designee is satisfied that: the Certificate Holder'/s quality control program is still in place, and they can fabricate code components in compliance with the applicable requirements in the ASME Boiler and Pressure Vessel Code.

- on the issuance of an ASME Certificate of Authorization for the first time

- when a current Certificate Holder'/s ASME Certificate of Authorization has expired prior to the date the renewal review was held, and no extension was granted by ASME due to the failure of the Certificate Holder to submit the renewal application and fees to ASME at least 3 months prior to the expiration date on the Certificate(s).

ASME may grant the request provided:

- The lapse in time from the expiration date on the old ASME Certificate of Authorization to the date of issuance or the new ASME Certificate of Authorization has not exceeded three months

- The review was conducted within the three-month period, but ASME was unable to process the review team recommendation within those three months.

For assessment of the QC System, the applicant must demonstrate sufficient administrative and fabrication functions to show that they have the knowledge and ability to produce the code items for the type of certification for which they have applied. Fabrication functions may be demonstrated using current work, a mock-up produced to current code rules, or a combination of the two. All elements of the QC System must be demonstrated.

Nuclear Material Organization Certification

- Submittal of the revised quality system manual, which should reflect the new name of the company, to ASME for acceptance.

- Confirmation that there have been no changes in key personnel within the organization that could affect the implementation of the quality system program as accepted by ASME.

- This name change does not alter the quality system program as previously accepted by ASME.

- Verification that the newly named entity is the same corporate entity as currently certified by ASME with the assurance that the company accepts responsibility for all ASME code activities previously performed with the Quality System Certificate number(s).

- Arranging for an audit to revise the QSC to reflect the new location'/s address. The audit team will consist of an ASME Team Leader; or

- Arranging for a survey to be conducted for early renew the QSC to reflect the new location. The survey team size will be determined upon receipt of completed application forms.

- The necessary changes have been made to the quality system manual to reflect the address change and a copy submitted to ASME for acceptance.

- Verification that there have been no changes in key personnel within your organization that could affect the implementation of your quality system program as accepted by ASME.

- Verification that the address change does not alter your quality system program as previously accepted by ASME.

Bioprocessing Equipment (BPE) Certification

Nuclear Component Certification

If an AIA audit is required, then ASME must receive a report from the Authorized Nuclear Inspector Supervisor (ANIS) which documents the following information to support the requested change:

- Summary of the review conducted by the ANIS, including how the Certificate Holder'/s quality assurance manual has been revised to reflect the relocation or new location and that the ANIS has reviewed and accepted the revisions.

- Verification that the relocation or the addition of the new location does not alter the quality assurance program as previously accepted by ASME.

- Verification that there have been no changes to key personnel within the Certificate Holder'/s organization that could affect the implementation of the quality assurance program as accepted by ASME.

- A recommendation covering judgment by the ANIS whether a need exists for an ASME audit.

If ASME determines that an ASME audit is required, then the Certificate Holder has the option of either:

- Arranging for an audit to revise the certificate(s) to reflect the new location'/s address. The audit team will consist of an ASME Team Leader and the AIA representative; or

- Arranging for a survey to be conducted for an early renewal of the certificate(s) to reflect the new location.

- Summary of the review conducted by ANIS including documentation as to how the Certificate Holder'/s quality assurance manual has been revised to reflect the storage of code material at the new facility and that the ANIS has reviewed and accepted the revisions to the manual.

- Verification that the new facility is for the storage of material only where fabrication, assembly, or construction activities are prohibited; that proper controls have been implemented to identify code material vs. non-code material and if applicable, for which the shipment of material as a material organization is prohibited.

- Verification that the additional location for the storage of code material does not alter the quality assurance program as previously accepted by ASME.

- Verification that there have been no changes to key personnel within the Certificate Holder'/s organization which could affect implementation of the quality assurance program as accepted by ASME.

- Summary of the review conducted by the Authorized Nuclear Inspector Supervisor (ANIS) including documentation as to how the Certificate Holder'/s quality assurance manual had been revised to reflect the expansion of Class 1 Authorization and that the ANIS has reviewed and accepted the revisions.

- Verification that the measures described in (a) above have been implemented.

- Concurrence by the AIA that the need exists for the requested change in scope of work, and a supporting recommendation for the scope revision.

- Verification that the AIA has an agreement with this company under their new name.

- Summary of the review conducted by the Authorized Nuclear Inspector Supervisor (ANIS) including documentation as to how the Certificate Holder'/s quality assurance manual has been revised to reflect the name change and that the ANIS has reviewed and accepted the revisions.

- Verification that this name change does not alter that quality assurance program as previously accepted by ASME.

- Verification that there have been no changes to key personnel within the Certificate Holder'/s organization that could affect the implementation of the quality assurance program as accepted by ASME

- A recommendation covering judgment by the AIA as to whether a need exists for an ASME audit.

- Verification that the newly named corporate entity is the same entity that is currently accredited by ASME.

ASME also requires a statement from the company that they accept responsibility for all ASME code activities previously performed with these certificate numbers.

- Verification that the AIA has an agreement with this company at the new address.

- Summary of the review conducted by the Authorized Nuclear Inspector Supervisor (ANIS) including documentation as to how the Certificate Holder'/s quality assurance manual had been revised to reflect the address change and that the ANIS has reviewed and accepted the revisions.

- Verification that the address change does not alter the company'/s quality assurance program as previously accepted by ASME.

- Verification that there have been no changes to key personnel within the Certificate Holder'/s organization that could affect the implementation of the quality assurance program as accepted by ASME.

- A recommendation covering judgment by the AIA whether a need exists for an ASME audit at the new location.