A Nuclear Microreactor Nears Reality

A Nuclear Microreactor Nears Reality

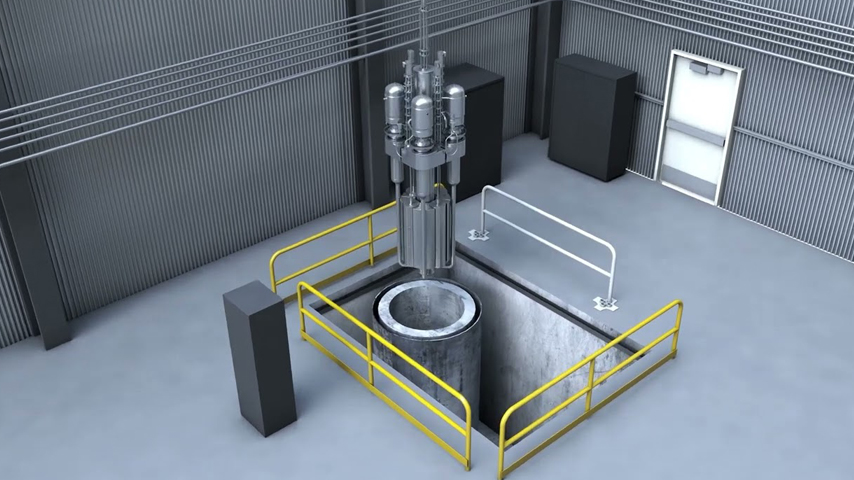

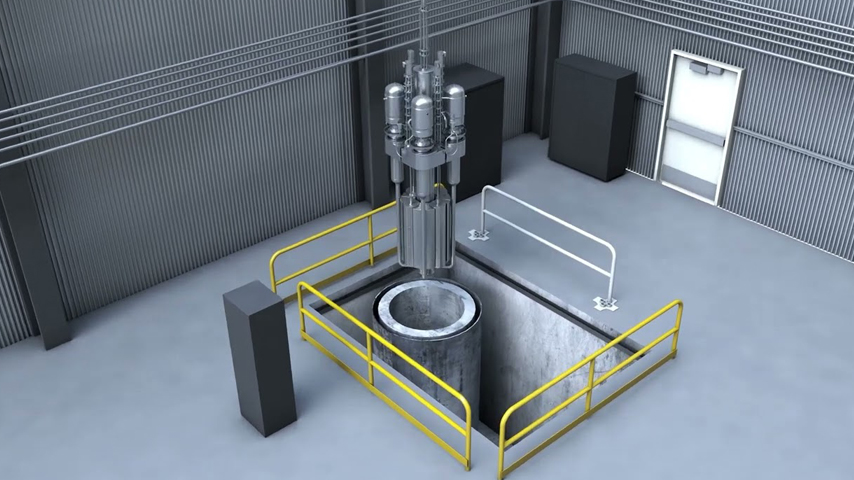

MARVEL nuclear microreactor is being developed at Idaho National Laboratory.

The road from concept to criticality, for new nuclear reactor designs, is a long long one. Regulations, complexity, finance, and wavering public support choke the path to operation, and as a result this U.S. hasn’t seen a new design move to operation in decades.

But now Yasir Arafat, a nuclear engineer at Idaho National Laboratory, is driven to get his tiny MARVEL ( Microreactor Applications Research Validation and EvaLuation) reactor up and running in what he hopes is a year or two from now.

"One of the things that has plagued the industry is that normally when you start a new nuclear design project there’s a lot of solving to do. There are physics problems to solve, analytical problems to solve, mathematical models to solve, engineering challenges, you name it,” he said. “And oftentimes things that are optimal on paper, in practice become quite challenging. Our objective is to build a microreactor, a test microreactor, but with a focus on technologies that we have the most data on, that we can either procure today from the existing supply chain or, if we have to make something, it must be able to be fabricated with relative ease.”

Become a Member: How to Join ASME

The result of that focus is a 12-foot-tall, 2,000-pound, 100-kilowatt-producing reactor that is well on its way to churning out its first stream of electricity. The trick to making this smaller, safer, faster reactor might be in the familiarity of the pieces, but the way they are being brought together is unique.

The micro-reactor will use liquid metal—a mix of sodium and potassium—as a coolant. Doing so results in an unpressurized reactor, which reduces the number of systems needed and keeps things simple.

"Water is the universal solvent,” Arafat said. “We have nearly 100 systems in current plants to keep the water pure and hot without boiling away. We have demineralizers, we have chemistry control systems, we have volume control systems, we have impurity removal, high and low pressure injection systems for safety, to name a few. We’ve got a ton of auxiliary systems so that water will actually work as a predictable coolant in a nuclear power plant.”

Liquid metal doesn’t demand the same treatment, is excellent at conducting heat, and doesn’t pressurize or vaporize like water.

More for You: SMRs Are Promising But Disposal Issues Remain

Other advanced reactor designs have shied from using sodium because of its energetic reaction with water. But the Experimental Breeder Reactor II, which ran for 30 years, used sodium as a coolant without an issue.

We have some people on my team who worked on the EBR II program. They said that before the reactor was commissioned, they had made markings inside the vessel,” Arafat said. “After 30 years of operation, they were able to see those markings on the wall. That's how little corrosion there was on the structural walls.”

The coolant is circulated with natural convection, so there’s no need for pumps, electricity to power them, or the backup systems and generators they would require. That keeps the reactor safe and simple but comes with a price: a pump would move the fluid at a higher rate allowing the MARVEL to generate 500 kilowatts-thermal instead of only 100 kilowatt-thermal.

Instead of turning to a traditional (and too large) steam turbine, they are specifying off-the-shelf Stirling engines, which was ideal to match the reactor’s 100-kW thermal energy. They don’t require the boiling of any water, and a heat exchanger will transfer heat from the reactor coolant directly to the heater head of the engine. Unlike light water reactors, which do their power conversion in separate buildings, the Stirling engines will be placed four-and-a-half feet from MARVEL’s core, helping to keep the footprint small.

Editor's Pick: Nuclear Coolant Pump Monitoring Boosted with Wavelets

But the real key to the reactor’s simplicity is the fuel it uses and the safety that comes with it. The uranium-zirconium hydride fuel—produced by TRIGA International—has been used in research reactors for more than 60 years.

So it’s a very familiar fuel that has pretty decent thermal properties and high uranium density,” Arafat said. It also has a “negative temperature feedback coefficient,” which means that it reacts less when it heats up. In other words, “As soon as you add a bunch of reactivity, at the quantum physics level it automatically kills the chain reaction.” Arafat said. “So, there’s no overheating, no cladding failure, no meltdown. From a safety perspective, this is a very ‘boring’ reactor. And that’s exactly the type of reactor we want.”

With support from the Department of Energy, MARVEL has already moved out of the “paper reactor” zone to a “practical reactor.” The developers now have a prototype constructed and ready for testing. Once they’ve done that, they’ll submit a “Preliminary Documented Safety Analysis,” and, if approved, will begin constructing the reactor. They have already begun purchasing the critical parts of the reactor for fabrication. “We hope to build the reactor by next summer,” Arafat said. “Speed was our metric of performance for MARVEL. Otherwise, you know, it will be irrelevant.”

Michael Abrams is a science and technology writer in Westfield, N.J.

But now Yasir Arafat, a nuclear engineer at Idaho National Laboratory, is driven to get his tiny MARVEL ( Microreactor Applications Research Validation and EvaLuation) reactor up and running in what he hopes is a year or two from now.

"One of the things that has plagued the industry is that normally when you start a new nuclear design project there’s a lot of solving to do. There are physics problems to solve, analytical problems to solve, mathematical models to solve, engineering challenges, you name it,” he said. “And oftentimes things that are optimal on paper, in practice become quite challenging. Our objective is to build a microreactor, a test microreactor, but with a focus on technologies that we have the most data on, that we can either procure today from the existing supply chain or, if we have to make something, it must be able to be fabricated with relative ease.”

Become a Member: How to Join ASME

The result of that focus is a 12-foot-tall, 2,000-pound, 100-kilowatt-producing reactor that is well on its way to churning out its first stream of electricity. The trick to making this smaller, safer, faster reactor might be in the familiarity of the pieces, but the way they are being brought together is unique.

The micro-reactor will use liquid metal—a mix of sodium and potassium—as a coolant. Doing so results in an unpressurized reactor, which reduces the number of systems needed and keeps things simple.

"Water is the universal solvent,” Arafat said. “We have nearly 100 systems in current plants to keep the water pure and hot without boiling away. We have demineralizers, we have chemistry control systems, we have volume control systems, we have impurity removal, high and low pressure injection systems for safety, to name a few. We’ve got a ton of auxiliary systems so that water will actually work as a predictable coolant in a nuclear power plant.”

Liquid metal doesn’t demand the same treatment, is excellent at conducting heat, and doesn’t pressurize or vaporize like water.

More for You: SMRs Are Promising But Disposal Issues Remain

Other advanced reactor designs have shied from using sodium because of its energetic reaction with water. But the Experimental Breeder Reactor II, which ran for 30 years, used sodium as a coolant without an issue.

We have some people on my team who worked on the EBR II program. They said that before the reactor was commissioned, they had made markings inside the vessel,” Arafat said. “After 30 years of operation, they were able to see those markings on the wall. That's how little corrosion there was on the structural walls.”

The coolant is circulated with natural convection, so there’s no need for pumps, electricity to power them, or the backup systems and generators they would require. That keeps the reactor safe and simple but comes with a price: a pump would move the fluid at a higher rate allowing the MARVEL to generate 500 kilowatts-thermal instead of only 100 kilowatt-thermal.

Instead of turning to a traditional (and too large) steam turbine, they are specifying off-the-shelf Stirling engines, which was ideal to match the reactor’s 100-kW thermal energy. They don’t require the boiling of any water, and a heat exchanger will transfer heat from the reactor coolant directly to the heater head of the engine. Unlike light water reactors, which do their power conversion in separate buildings, the Stirling engines will be placed four-and-a-half feet from MARVEL’s core, helping to keep the footprint small.

Editor's Pick: Nuclear Coolant Pump Monitoring Boosted with Wavelets

But the real key to the reactor’s simplicity is the fuel it uses and the safety that comes with it. The uranium-zirconium hydride fuel—produced by TRIGA International—has been used in research reactors for more than 60 years.

So it’s a very familiar fuel that has pretty decent thermal properties and high uranium density,” Arafat said. It also has a “negative temperature feedback coefficient,” which means that it reacts less when it heats up. In other words, “As soon as you add a bunch of reactivity, at the quantum physics level it automatically kills the chain reaction.” Arafat said. “So, there’s no overheating, no cladding failure, no meltdown. From a safety perspective, this is a very ‘boring’ reactor. And that’s exactly the type of reactor we want.”

With support from the Department of Energy, MARVEL has already moved out of the “paper reactor” zone to a “practical reactor.” The developers now have a prototype constructed and ready for testing. Once they’ve done that, they’ll submit a “Preliminary Documented Safety Analysis,” and, if approved, will begin constructing the reactor. They have already begun purchasing the critical parts of the reactor for fabrication. “We hope to build the reactor by next summer,” Arafat said. “Speed was our metric of performance for MARVEL. Otherwise, you know, it will be irrelevant.”

Michael Abrams is a science and technology writer in Westfield, N.J.

Pulse of the Profession: CAD in 2030

CAD technologies and their applications are rising in tandem with trends in Industry 4.0.