Turning Textiles into Pneumatic-Driven Computers

Turning Textiles into Pneumatic-Driven Computers

Rice engineers have designed fluidic logic elements into garments to help people with functional limitations perform tasks without electronic assistance. Courtesy of the Preston Innovation Lab.

Engineers are using the latest ideas and technologies to make “smart” textiles, which integrate electronics and textiles to create wearable clothing that can assist wearers in daily tasks. Researchers are intent on advancing the smart capabilities of “e-textiles” to increase their functionality so they can do more.

Researchers at Rice University’s George R. Brown School of Engineering have taken this thinking to the next level. Led by Dan Preston, assistant professor of mechanical engineering, the research team has prototyped a textile-based pneumatic computer that is capable of digital logic, onboard memory, and user interaction, and that can be worn as clothing.

“Our goal was to develop a controller that could be integrated seamlessly and unobtrusively into clothing, worn comfortably, and washed like regular garments,” said Preston. “This required developing a scalable logic architecture that can be embedded within two-dimensional compliant sheets, such as textiles.”

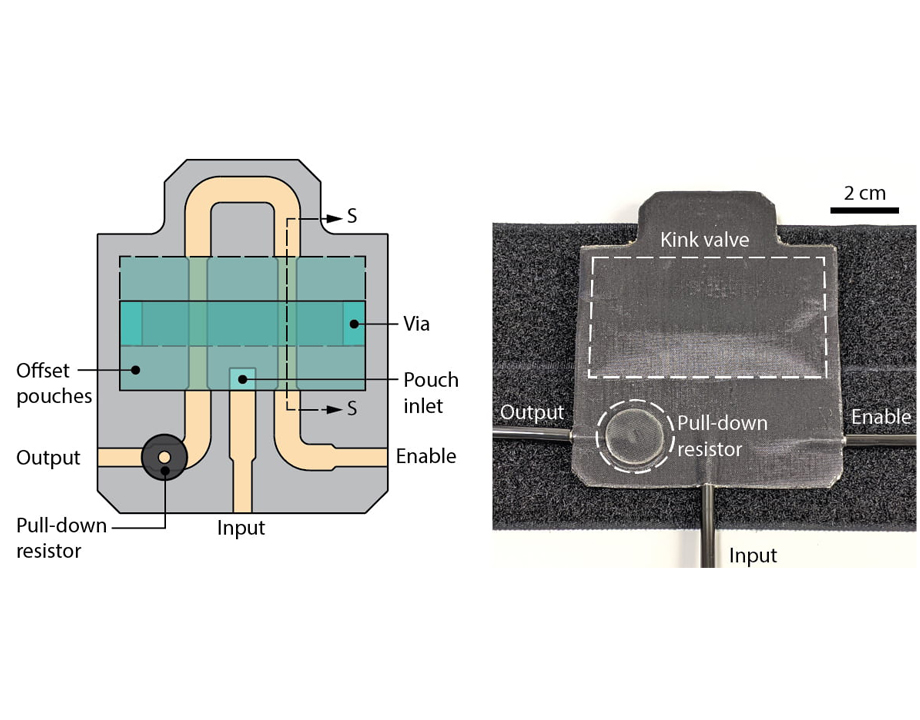

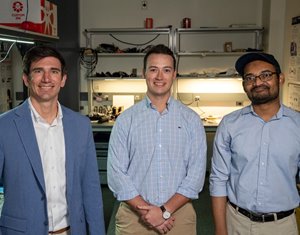

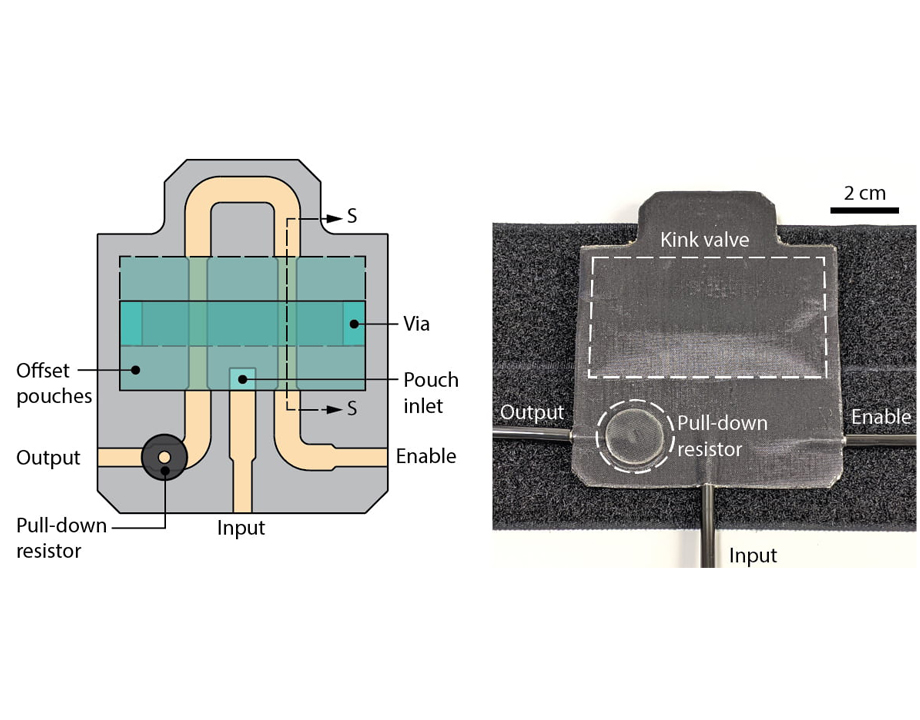

Preston’s invention is based on the process of "fluidic digital logic," which results when air flows through a series of "kinked" channels to form bits, the 1s and 0s in computer memories. By having textile-based logic gates that can support pneumatic actuators, with a push of a button the pneumatic computer could assist people with functional limitations to complete daily tasks more easily.

Similar To This: A Dye-removing Polymer That Cleans Water

"The idea of using fluids to construct digital logic circuits is not new," said Preston. "And in fact, in the last decade, people have been moving toward implementing fluidic logic in soft materials such as elastomers. But no one had taken the step to implement it in sheet-based materials, which is a first.”

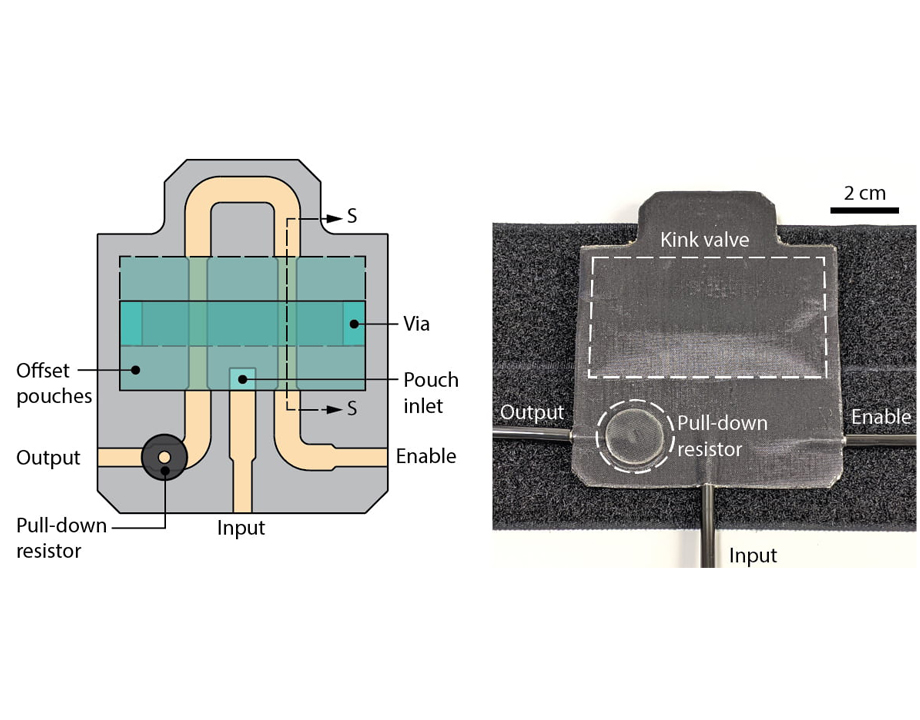

A key component of the device is a NOT gate (an inverter). This logic gate's output is the inverse of the input. For an electronic circuit, the gate is on or off (1 or 0), but with a pneumatic gate those terms become "high" or "low" air pressure.

The pneumatic system uses pressure-controlled valves that restrict the flow of air to start or stop an action. The valves, each about a square inch in size, are laminated into the textiles and have proven to be very sturdy devices.

“We were pleasantly surprised at how durable our textile logic gates turned out to be,” stated Anoop Rajappan, a Rice University postdoctoral fellow and research team member. “They were undamaged after being switched on and off 20,000 times, folded in half one million times, washed 20 times in a washing machine, and even run over with a pickup truck.”

Related Content: Innovations in Soft Robotics Research

Preston’s team is now looking into incorporating sensing intent. As soon as the wearer initiates a course of action, the system will then offer assistance to complete that action. “For example, if you start to grasp an object, and the system senses your intent, it will give you some assistance in closing your hand around that object so you can lift it up,” said Preston.

There is great potential for combining the comfort and look of textiles with the functionality, connectivity, and intelligence of sensors and electronics.

“The idea of textile-based pneumatic actuation and control has interesting parallels to traditional hydraulic and pneumatic circuits using pistons, cylinders, and valves,” said Rajappan. “Engineers designing assistive mechanisms and technologies might also find our textile-based approach to actuation and control interesting.”

Another plus is that the technique the team developed for creating the fluidic channels and spaces in the textile laminates (selectively masking regions of heat-sealable fabric before thermal bonding) is readily scalable for mass production and could be applied in a wide range of applications. An example would be a hood-lift actuator for an outdoor jacket that is activated by the push of a button on the textile-integrated controller. Another would be an arm-lift actuator that helps the user raise his or her arm.

Sign up: ASME Membership Benefits

The next step for Preston is designing textile-based fluidic analogs to resistors, capacitors, and relays for greater functionality and performance, especially for wearable robots.

“Fluidic actuation in general has underpinned a majority of new technology in the growing field of soft robotics,” said Preston. “Pneumatic actuation in particular offers promise for soft wearable robots and devices that assist human motion by enabling lightweight, comfortable designs. I expect to see widespread use of commercially available assistive technologies that rely on pneumatic actuation within the next decade.”

Mark Crawford is technology writer based in Corrales, N.M.

Researchers at Rice University’s George R. Brown School of Engineering have taken this thinking to the next level. Led by Dan Preston, assistant professor of mechanical engineering, the research team has prototyped a textile-based pneumatic computer that is capable of digital logic, onboard memory, and user interaction, and that can be worn as clothing.

“Our goal was to develop a controller that could be integrated seamlessly and unobtrusively into clothing, worn comfortably, and washed like regular garments,” said Preston. “This required developing a scalable logic architecture that can be embedded within two-dimensional compliant sheets, such as textiles.”

Preston’s invention is based on the process of "fluidic digital logic," which results when air flows through a series of "kinked" channels to form bits, the 1s and 0s in computer memories. By having textile-based logic gates that can support pneumatic actuators, with a push of a button the pneumatic computer could assist people with functional limitations to complete daily tasks more easily.

Similar To This: A Dye-removing Polymer That Cleans Water

"The idea of using fluids to construct digital logic circuits is not new," said Preston. "And in fact, in the last decade, people have been moving toward implementing fluidic logic in soft materials such as elastomers. But no one had taken the step to implement it in sheet-based materials, which is a first.”

A key component of the device is a NOT gate (an inverter). This logic gate's output is the inverse of the input. For an electronic circuit, the gate is on or off (1 or 0), but with a pneumatic gate those terms become "high" or "low" air pressure.

The pneumatic system uses pressure-controlled valves that restrict the flow of air to start or stop an action. The valves, each about a square inch in size, are laminated into the textiles and have proven to be very sturdy devices.

“We were pleasantly surprised at how durable our textile logic gates turned out to be,” stated Anoop Rajappan, a Rice University postdoctoral fellow and research team member. “They were undamaged after being switched on and off 20,000 times, folded in half one million times, washed 20 times in a washing machine, and even run over with a pickup truck.”

Related Content: Innovations in Soft Robotics Research

Preston’s team is now looking into incorporating sensing intent. As soon as the wearer initiates a course of action, the system will then offer assistance to complete that action. “For example, if you start to grasp an object, and the system senses your intent, it will give you some assistance in closing your hand around that object so you can lift it up,” said Preston.

There is great potential for combining the comfort and look of textiles with the functionality, connectivity, and intelligence of sensors and electronics.

“The idea of textile-based pneumatic actuation and control has interesting parallels to traditional hydraulic and pneumatic circuits using pistons, cylinders, and valves,” said Rajappan. “Engineers designing assistive mechanisms and technologies might also find our textile-based approach to actuation and control interesting.”

Another plus is that the technique the team developed for creating the fluidic channels and spaces in the textile laminates (selectively masking regions of heat-sealable fabric before thermal bonding) is readily scalable for mass production and could be applied in a wide range of applications. An example would be a hood-lift actuator for an outdoor jacket that is activated by the push of a button on the textile-integrated controller. Another would be an arm-lift actuator that helps the user raise his or her arm.

Sign up: ASME Membership Benefits

The next step for Preston is designing textile-based fluidic analogs to resistors, capacitors, and relays for greater functionality and performance, especially for wearable robots.

“Fluidic actuation in general has underpinned a majority of new technology in the growing field of soft robotics,” said Preston. “Pneumatic actuation in particular offers promise for soft wearable robots and devices that assist human motion by enabling lightweight, comfortable designs. I expect to see widespread use of commercially available assistive technologies that rely on pneumatic actuation within the next decade.”

Mark Crawford is technology writer based in Corrales, N.M.