Spinning a Bandage

Spinning a Bandage

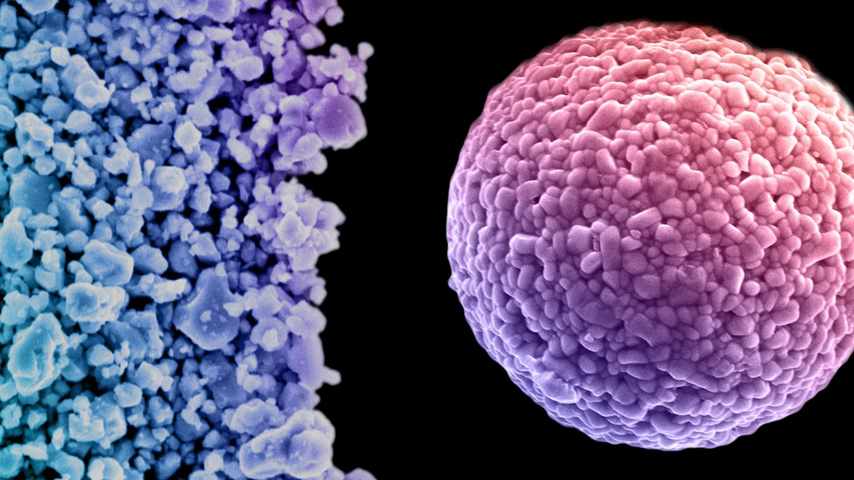

Breathable skin substitute is applied through a portable electrospinning device directly on a wound. Image: Nanomedic Technologies

Burn wounds are notoriously painful, and the healing process can be also with changings of dressings and medicines that pressure and coat the wound. Some of that could be alleviated with a new medical device, a portable electrospinner that produces and applies a synthetic nanofibrous material directly to a wound to promote healing. Its flexibility allows a patient to move more easily and can be easily peeled off.

Electrospinning is an old and proven technology to produce polymer fibers of nanoscale diameters. It works well but generally requires large equipment and a high-voltage direct current source of electricity, often in a clean room. That makes it unavailable for local use. Developers at NanoMedic, a Lod, Israel-based biomedical firm, miniaturized the technology for a hand-held electrospinning gun that applies a medicinal dressing directly to a wound.

Gary Sagiv, a NanoMedic executive, said Spincare uses the firm’s proprietary Electrospun Healing Fiber technology. It provides a transparent protective physical barrier, allowing medical professionals to monitor the healing process. The unique matrix was developed inhouse and structurally mimics the human extracellular matrix, he said, and can be enhanced with a variety of additives―from antimicrobial, collagen, and adhesive materials, to embedded human cells―for a wide range of complex clinical applications.

The firm will not comment on the application’s makeup, but its researchers have been working on the device for three years. NanoMedic’s parent company, NiCast, used traditional electrospinning techniques. When it moved into the medical device field, it created NanoMedic to develop the miniaturized device.

Editor's Pick: Bioengineering Blog: Pandemic Accelerates Shift to Digital Healthcare

According to the firm, the work correlates to the world's first electronic general-purpose computer ENIAC of the late 1940’s. “ENIAC took up over 167 square meters of space, was awfully expensive to build and utilized a lot of power. The same with the Spincare System―the challenges were the same, optimization of all the electronics, minimalizing integrated circuits, shrinking the PCBs and converting the extreme power supply into a force that could be portable without compromising the functionality, capabilities, and proficiency of the system.

“Most important, the miniaturization process could not affect the final architecture of the nanofibers, the electrostatic field of the electrospinning emission, and the way that it “organizes” the nanofiber matrix,” Sagiv said.

The matrix itself is printed directly on a wound, “that biomics the structure of the human extracellular matrix,” according to the firm, and is an “excellent” medium for drug delivery and tissue regeneration. It adheres to the wound, and is permeable and breathable. It gives the patient greater mobility and allows them to shower.

Reader's Choice: Video: Emerging Trends in Additive for Medical Applications

The device is being used in Europe and Israel and is being readied for review by the Food and Drug Administration in the U.S. Published reports said it has performed well on superficial wounds, although less affective on deeper wounds or burns. The company does not claim that the system is effective on such injuries.

There is debate within the medical community about the frequency of changing bandages to treat burns. Some recent advanced dressings already can be left on longer than traditional dressings. Spincare is representative of the view to dress the wound and provide protection or medication until it heals. NanoMedic claims that wound care treatments using synthetic dermal replacements have the potential to significantly reduce treatment costs of complex wounds.

John Kosowatz is senior editor.

Electrospinning is an old and proven technology to produce polymer fibers of nanoscale diameters. It works well but generally requires large equipment and a high-voltage direct current source of electricity, often in a clean room. That makes it unavailable for local use. Developers at NanoMedic, a Lod, Israel-based biomedical firm, miniaturized the technology for a hand-held electrospinning gun that applies a medicinal dressing directly to a wound.

Gary Sagiv, a NanoMedic executive, said Spincare uses the firm’s proprietary Electrospun Healing Fiber technology. It provides a transparent protective physical barrier, allowing medical professionals to monitor the healing process. The unique matrix was developed inhouse and structurally mimics the human extracellular matrix, he said, and can be enhanced with a variety of additives―from antimicrobial, collagen, and adhesive materials, to embedded human cells―for a wide range of complex clinical applications.

The firm will not comment on the application’s makeup, but its researchers have been working on the device for three years. NanoMedic’s parent company, NiCast, used traditional electrospinning techniques. When it moved into the medical device field, it created NanoMedic to develop the miniaturized device.

Editor's Pick: Bioengineering Blog: Pandemic Accelerates Shift to Digital Healthcare

According to the firm, the work correlates to the world's first electronic general-purpose computer ENIAC of the late 1940’s. “ENIAC took up over 167 square meters of space, was awfully expensive to build and utilized a lot of power. The same with the Spincare System―the challenges were the same, optimization of all the electronics, minimalizing integrated circuits, shrinking the PCBs and converting the extreme power supply into a force that could be portable without compromising the functionality, capabilities, and proficiency of the system.

“Most important, the miniaturization process could not affect the final architecture of the nanofibers, the electrostatic field of the electrospinning emission, and the way that it “organizes” the nanofiber matrix,” Sagiv said.

The matrix itself is printed directly on a wound, “that biomics the structure of the human extracellular matrix,” according to the firm, and is an “excellent” medium for drug delivery and tissue regeneration. It adheres to the wound, and is permeable and breathable. It gives the patient greater mobility and allows them to shower.

Reader's Choice: Video: Emerging Trends in Additive for Medical Applications

The device is being used in Europe and Israel and is being readied for review by the Food and Drug Administration in the U.S. Published reports said it has performed well on superficial wounds, although less affective on deeper wounds or burns. The company does not claim that the system is effective on such injuries.

There is debate within the medical community about the frequency of changing bandages to treat burns. Some recent advanced dressings already can be left on longer than traditional dressings. Spincare is representative of the view to dress the wound and provide protection or medication until it heals. NanoMedic claims that wound care treatments using synthetic dermal replacements have the potential to significantly reduce treatment costs of complex wounds.

John Kosowatz is senior editor.