Manufacturing and National Security

Manufacturing and National Security

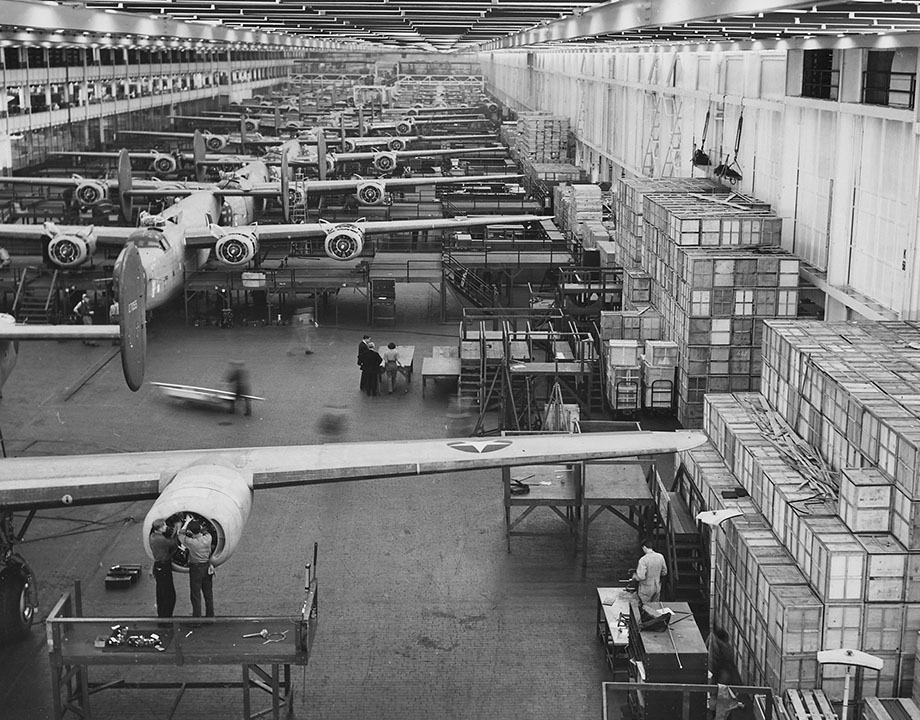

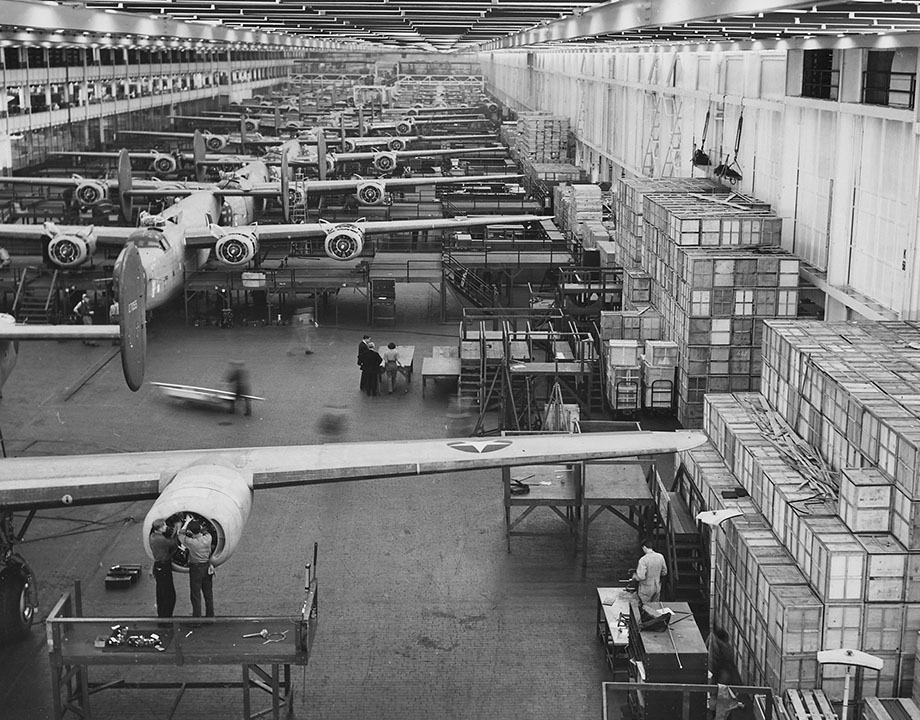

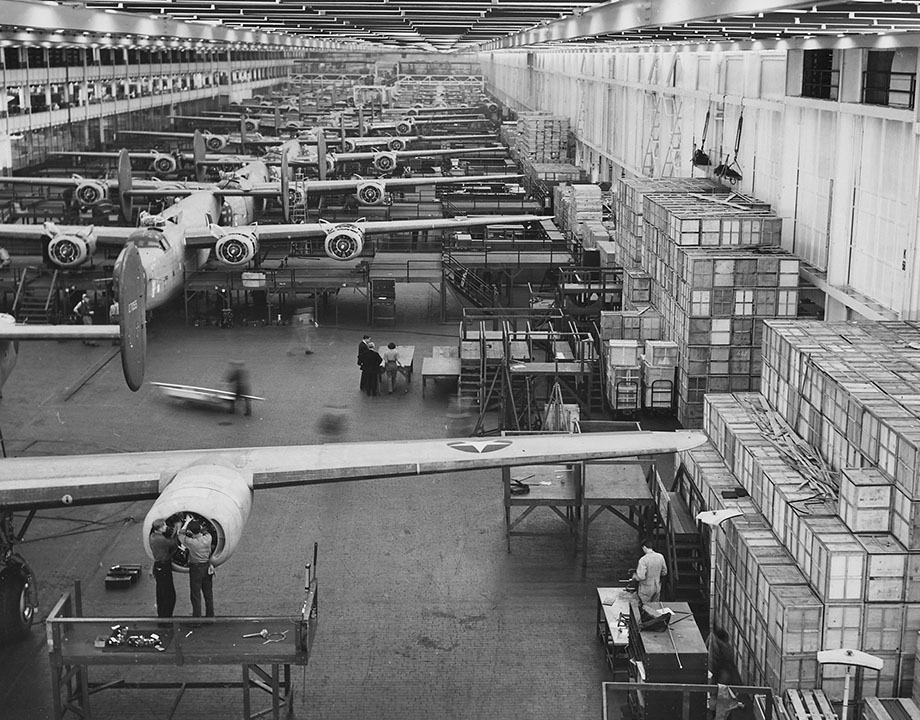

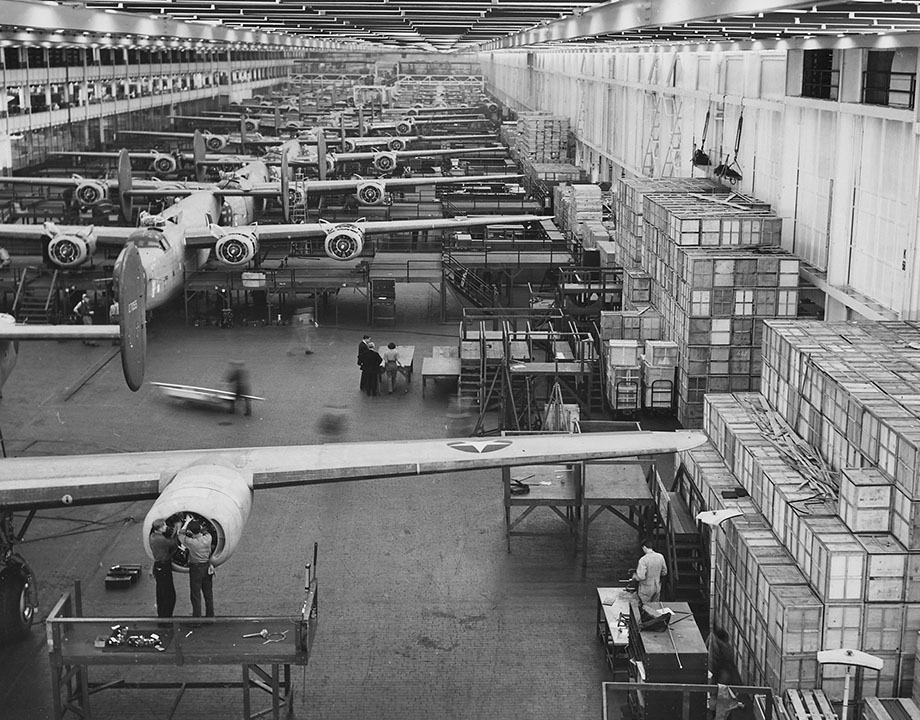

A strong manufacturing sector is essential to supporting America’s military operations and global commitments. Photo of World War II-era Willow Run factory: The Detroit News Archives

Discussions around national security are full of aphorisms. One of the most enduring was coined in 1979 by Gen. Robert H. Burrow, commandant of the Marine Corps, who was quoted in a newspaper interview saying, “Amateurs talk about strategy and tactics. Professionals talk about logistics and sustainability in warfare.”

In the economic sector, logistics refers to the ability to establish and maintain a supply chain—the movement of material, information, energy, and all other resources necessary to produce a product and deliver it to market. From a military standpoint, this coordination and movement of resources represents the transport of all the items needed to support a warfighter in a conflict, ending with the culmination of resources at the assigned location just as it is needed. Fail at that, and all the effort on strategy and tactics is wasted.

The connection between industrial logistics and military logistics is deep. The U.S. Department of Defense (DOD) is one of the world's largest procurement organizations. In addition to weapons systems, the military purchases a plethora of products, both consumable and non-consumable, in the execution of its duties. It is one of the largest industrial customers in the world.

Like many manufacturing companies, the modern military strives for just-in-time response and agility; and the military requires all manner of manufactured goods to fill its supply chain. Unfortunately, a 2018 report conducted in response to a Presidential Executive Order noted that the DOD currently has a “surprising level of foreign dependence on competitor nations.” Without domestic advanced manufacturing capability in relevant technology areas, the ability of U.S. military to respond in an agile manner is significantly compromised.

Therefore, the DOD cannot view manufacturing capability from the lens of procurement alone. It must take a holistic view of the entire supply chain, including science and technology development and manufacturing. For the military to maintain these effective logistics systems, it requires a strong manufacturing base to support the logistics frameworks in place and provide manufactured goods for distribution. It also needs the capability of integrating evolving technological advances into these frameworks.

A glimpse of potential vulnerability was provided at the start of the COVID-19 crisis in early 2020. American companies with offshore factories saw some of their facilities nationalized and unable to fulfill their upstream supply chain obligations. It wasn’t only overseas factories that were affected; production facilities in North America were nationalized or unavailable as borders were closed. Beyond the disruption to consumers, this was a shock to military planners, who had long considered the manufacturing capability of Canada and Mexico to be blockade-proof and as reliable as domestic manufacturing.

Manufacturing is such a critical aspect of military planning and national security that choke points—portions of supply chains that are unreliable and susceptible to disruption—must be mitigated at all costs. In the absence of suitable domestic suppliers, military planners must rapidly identify alternate suppliers and ensure a stockpile of necessary equipment.

There is one more factor to consider: Military advances (such as weapons systems, transport, communications) often align with dual-use domestic technologies and sophisticated production developments, with the co-exploitation of advanced technologies serving as the norm, not the exception. New technological advances play a role in determining military engagement and advancement. If the new technology cannot be produced on-demand and at requisite scale, this directly impacts military strategy.

This reliance on technology and the need for manufacturing capability was noted in the 2012 President's Executive Order 13603. “The United States must have an industrial and technological base capable of meeting national defense requirements and capable of contributing to the technological superiority of its national defense equipment in peacetime and in times of national emergency,” the order states. “The domestic industrial and technological base is the foundation for national defense preparedness."

Defense industry leadership: 6 Questions with Raytheon’s Laura McGill

The reference to two executive orders, issued by presidents from separate administrations, underlines the fact that the importance of manufacturing to national security is recognized by defense professionals across the political spectrum. And yet, investments in American manufacturing infrastructure have fallen behind other nations, exacerbating security concerns. As a new administration sets its course for both economic and security policy, there is an opportunity for new investments in infrastructure, education, and research and development to support advanced manufacturing that can enhance national defense.

Generations of Americans understand the military implications of manufacturing. When the United States was caught without enough tanks, planes, and other equipment upon entry into the Second World War, factories and shipyards were converted from civilian products to military needs. During the Cold War, it was expected that military conflict would occur in Europe between major powers using large, expensive systems such as tanks, bombers, missiles, and ships.

The attacks of September 11, 2001, forced a change in the thinking and application of military prowess vis à vis national security. The focus shifted from armored divisions to surveillance, drones, intelligence, and special forces. In response to new threats, U.S. military technological capabilities also need to evolve.

Another evolution is currently taking place. The most recent National Defense Strategy, published in 2018, notes that every domain of military operations—air, ground, water, and space—is currently under threat. The report notes the need for the continuous rapid production and deployment of advanced technologies, but also recognizes a fundamental security dilemma: These advanced technologies are expected to derive from the commercial sector, which enables competitor nations and non-state actors to potentially gain access to them.

The nature of technology in this age is one of constant evolution and advancement. While one of the enduring strengths of the United States is its open, free-market economic system, the nature of today’s bleeding-edge technologies and worldwide communications systems means that a global supply chain presents a significant risk to the military. Foreign-sourced technologies cannot be reliably obtained during conflict, as adversaries can apply force or soft power to disrupt the supply chain, leading to potentially catastrophic shortages.

Further, foreign-designed and manufactured technologies have a risk and may even be exploited by potential adversaries to the detriment of the U.S. For several years there has been a concern that electronics manufactured in potential adversary states may contain hidden systems that could be accessed by foreign militaries. Even software and services must be examined for these sorts of vulnerabilities.

To effectively harness advanced military technology while eliminating (or at least greatly reducing) the risk of foreign sabotage, the U.S. must have a vibrant innovation culture and domestic manufacturing infrastructure scaled to national security needs. That culture and infrastructure must be a focus of continuous growth and investment, as any advantages in military technology will be fleeting. A pipeline of innovations, derived from a world-leading commitment to basic and applied research is essential for continued military preparedness. This also requires a world-class workforce and agile industrial sector that can quickly translate research results into new products and produce them at scale.

More on this topic: Navy Sails Into Supply Chain with Metal 3D Printing

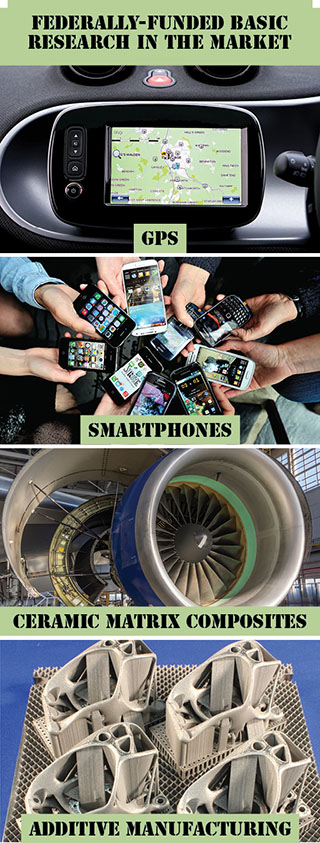

These attributes align well with the strategic objectives addressing domestic supply chain capabilities identified in Strategy for American Leadership in Advanced Manufacturing, a report published by the National Science and Technology Council. It should be noted that any nation that makes such investments in its domestic manufacturing sector improves its national security position as well. Indeed, products and services that have emerged from federally funded research, including military projects, include GPS, modern smartphone technologies, computer numerical control machine tools, additive manufacturing, polymer and ceramic matrix composites, and countless more.

Research and development can be a somewhat nebulous term. Some government agencies differentiate between basic research, applied research, and development or design efforts. To better reflect some of the different activities within these catch-all terms, the DOD uses a more detailed approach, using nine technology readiness levels (TRL) and manufacturing readiness levels (MRL) to guide its planning and investment in new technologies—roughly, TRL 1-3 for basic research, 4-7 for applied, and 8-9 for development/design.

The differences between basic and applied research are worth unpacking.

Basic research is conducted for the purpose of advancing scientific knowledge. Though it often does not have immediate commercial objectives, successful basic research can reap a high payoff as it can introduce new science that can revolutionize old methodologies. But it also entails long lead times, high cost, and high risk; even when successful it may not be immediately translated into practice. Because of this uncertainty and long lead time, basic research in the U.S. is predominantly funded by the federal government.

Often, basic research is thought of in reference to space exploration or high-energy physics, but it can also fund small projects that can grow, unexpectedly, into giants. Perhaps the most dramatic demonstration of the impact of basic research is a little-referenced National Science Foundation grant in the Digital Library Initiative program to Stanford University, which included funding for graduate students Larry Page and Sergey Brin; within three years, their research on ranking matching pages on the World Wide Web became the basis for the company they founded in a friend’s garage. In 1998, Page and Brin incorporated Google, Inc. (As an illustration of the value of basic research, the tax revenues stemming from Google, its employees, and the add on effects throughout the economy greatly exceed the cumulative expenditures of the National Science Foundation since its founding in 1950.)

Applied research is more directed. It seeks to solve a specific problem and often requires the same level of creativity and scientific discovery, but it focuses on technologies that enable translation of scientific knowledge to commercialization at scale. Often, new manufacturing approaches are needed and require investigation, product features are redesigned to facilitate manufacture, and significant knowledge and value is embedded into the product. Because many promising breakthroughs discovered in basic research fail to move out of this stage, it is commonly referred to as the “valley of death.”

Unlike basic research, applied research historically was conducted and funded by industry. However, many countries employ extensive programs to subsidize expenditures in applied manufacturing research. The Made in China 2025 and associated programs, investing at least $1.4 trillion over 10 years, has raised eyebrows for its ambition. However, the German federal and state governments, through the Fraunhofer program, provide $2 billion that is matched by another $1 billion in industry match in a public-private partnership. Started with U.S. Marshall Plan funding after World War II, the Fraunhofer program is widely considered the most successful long-term commitment to manufacturing investment in the world. Canada, South Korea, the United Kingdom, and other nations make similar investments. It has been often demonstrated that manufacturing is located near the scale-up and manufacturing research, in order to capture the acquired knowledge in production.

Frontiers of advanced manufacturing: Lakshmi Vendra Reviews AM’s Use in Oil and Gas

American industry has lacked this scale of funding and its leadership in manufacturing has seriously eroded during the past few decades. The Manufacturing USA program, which is similar in focus and aspirations to the Fraunhofer program, has invested only $1 billion—total—in federal funding since its inception in 2012.

Recognizing that military innovations often emerge from the commercial sector, the Department of Defense has been the largest funding source for Institutes in the Manufacturing USA program. Indeed, the technological focus of many of these institutes aligns with anticipated procurement needs, from advanced lightweight metal manufacturing to the industrial production of biological solutions for injured veterans. However, just as military applications arise from industry technologies, industry can exploit manufacturing research directed toward military applications. The result is an innovation ecosystem that is much larger and impactful than the government funding and which can have demonstrable value from both a national security and economic competitiveness standpoint.

As the United States enters the third decade of the 21st century, its national security landscape is changing. To meet new challenges, a greater commitment is needed to an innovation pipeline and manufacturing capability that can provide new military capabilities (including logistics). Other nations invest far more than the United States in public-private partnerships in manufacturing, as well as in manufacturing and engineering-based research. If the United States continues to lag adversaries and competitor nations—and remains dependent on other countries for components produced via advanced manufacturing—it could discover that it is unable to maintain its military advantage in future conflicts.

Editor's Choice: Advancing Additive Manufacturing in Aerospace

Some steps that could be taken to shore up the U.S. position include expanding the Manufacturing USA program and (as proposed in the Endless Frontiers Act introduced in Congress in 2020) establishing a second branch to the National Science Foundation that focuses on translational R&D including manufacturing. This development would place a stronger focus on manufacturing innovation and is consistent with the investment priorities of other industrialized nations. The lack of consistent funding has been a drawback—industry cannot plan to partner with the federal government when long-term commitments are uncertain.

More ambitiously, the government could establish a holistic approach to federal funding of manufacturing R&D. Nurturing of public-private partnerships in translational research is practiced worldwide, and a consistent commitment to this investment is needed in the U.S. Such a new approach could span the continuum from basic to applied research, tracking the progression of technologies (through periodic road-mapping) to ensure successful transition to market. State and federal government investments could also expand manufacturing education and workforce development investments that span high schools through community and technical colleges to doctoral degree granting institutions, in order to ensure that the next generation of American manufacturing workforce is trained using state-of-the-art infrastructure. (The potential demand by industry for skilled manufacturing workers is currently anticipated to outstrip demand by 2 million by 2030.)

National security requires maintaining a world-class manufacturing sector and promoting a perpetual innovation culture in the United States. The battles of tomorrow are being won—or lost—in university and industrial research labs today.

Steven R. Schmid is the Belk-Woodward Distinguished Professor of Engineering at the University of North Carolina at Charlotte and an ASME Fellow. Schmid also is an associate editor of the Journal of Manufacturing Science and Engineering. Shreyes N. Melkote is also an ASME Fellow and holds the Morris M. Bryan Jr. Professorship in Mechanical Engineering at the Georgia Institute of Technology in Atlanta as well as serves as associate director of the Georgia Tech Manufacturing Institute. Both serve on the ASME Manufacturing Public Policy Task Team, where Schmid is the chair. The authors gratefully acknowledge the helpful comments of Robert S. (Scott) Frost, Distinguished Analyst, ANSER, in the preparation and review of this manuscript.

In the economic sector, logistics refers to the ability to establish and maintain a supply chain—the movement of material, information, energy, and all other resources necessary to produce a product and deliver it to market. From a military standpoint, this coordination and movement of resources represents the transport of all the items needed to support a warfighter in a conflict, ending with the culmination of resources at the assigned location just as it is needed. Fail at that, and all the effort on strategy and tactics is wasted.

The connection between industrial logistics and military logistics is deep. The U.S. Department of Defense (DOD) is one of the world's largest procurement organizations. In addition to weapons systems, the military purchases a plethora of products, both consumable and non-consumable, in the execution of its duties. It is one of the largest industrial customers in the world.

Like many manufacturing companies, the modern military strives for just-in-time response and agility; and the military requires all manner of manufactured goods to fill its supply chain. Unfortunately, a 2018 report conducted in response to a Presidential Executive Order noted that the DOD currently has a “surprising level of foreign dependence on competitor nations.” Without domestic advanced manufacturing capability in relevant technology areas, the ability of U.S. military to respond in an agile manner is significantly compromised.

Therefore, the DOD cannot view manufacturing capability from the lens of procurement alone. It must take a holistic view of the entire supply chain, including science and technology development and manufacturing. For the military to maintain these effective logistics systems, it requires a strong manufacturing base to support the logistics frameworks in place and provide manufactured goods for distribution. It also needs the capability of integrating evolving technological advances into these frameworks.

A glimpse of potential vulnerability was provided at the start of the COVID-19 crisis in early 2020. American companies with offshore factories saw some of their facilities nationalized and unable to fulfill their upstream supply chain obligations. It wasn’t only overseas factories that were affected; production facilities in North America were nationalized or unavailable as borders were closed. Beyond the disruption to consumers, this was a shock to military planners, who had long considered the manufacturing capability of Canada and Mexico to be blockade-proof and as reliable as domestic manufacturing.

Manufacturing is such a critical aspect of military planning and national security that choke points—portions of supply chains that are unreliable and susceptible to disruption—must be mitigated at all costs. In the absence of suitable domestic suppliers, military planners must rapidly identify alternate suppliers and ensure a stockpile of necessary equipment.

There is one more factor to consider: Military advances (such as weapons systems, transport, communications) often align with dual-use domestic technologies and sophisticated production developments, with the co-exploitation of advanced technologies serving as the norm, not the exception. New technological advances play a role in determining military engagement and advancement. If the new technology cannot be produced on-demand and at requisite scale, this directly impacts military strategy.

This reliance on technology and the need for manufacturing capability was noted in the 2012 President's Executive Order 13603. “The United States must have an industrial and technological base capable of meeting national defense requirements and capable of contributing to the technological superiority of its national defense equipment in peacetime and in times of national emergency,” the order states. “The domestic industrial and technological base is the foundation for national defense preparedness."

Defense industry leadership: 6 Questions with Raytheon’s Laura McGill

The reference to two executive orders, issued by presidents from separate administrations, underlines the fact that the importance of manufacturing to national security is recognized by defense professionals across the political spectrum. And yet, investments in American manufacturing infrastructure have fallen behind other nations, exacerbating security concerns. As a new administration sets its course for both economic and security policy, there is an opportunity for new investments in infrastructure, education, and research and development to support advanced manufacturing that can enhance national defense.

Industrial Leadership

Generations of Americans understand the military implications of manufacturing. When the United States was caught without enough tanks, planes, and other equipment upon entry into the Second World War, factories and shipyards were converted from civilian products to military needs. During the Cold War, it was expected that military conflict would occur in Europe between major powers using large, expensive systems such as tanks, bombers, missiles, and ships.

The attacks of September 11, 2001, forced a change in the thinking and application of military prowess vis à vis national security. The focus shifted from armored divisions to surveillance, drones, intelligence, and special forces. In response to new threats, U.S. military technological capabilities also need to evolve.

Another evolution is currently taking place. The most recent National Defense Strategy, published in 2018, notes that every domain of military operations—air, ground, water, and space—is currently under threat. The report notes the need for the continuous rapid production and deployment of advanced technologies, but also recognizes a fundamental security dilemma: These advanced technologies are expected to derive from the commercial sector, which enables competitor nations and non-state actors to potentially gain access to them.

The nature of technology in this age is one of constant evolution and advancement. While one of the enduring strengths of the United States is its open, free-market economic system, the nature of today’s bleeding-edge technologies and worldwide communications systems means that a global supply chain presents a significant risk to the military. Foreign-sourced technologies cannot be reliably obtained during conflict, as adversaries can apply force or soft power to disrupt the supply chain, leading to potentially catastrophic shortages.

Further, foreign-designed and manufactured technologies have a risk and may even be exploited by potential adversaries to the detriment of the U.S. For several years there has been a concern that electronics manufactured in potential adversary states may contain hidden systems that could be accessed by foreign militaries. Even software and services must be examined for these sorts of vulnerabilities.

To effectively harness advanced military technology while eliminating (or at least greatly reducing) the risk of foreign sabotage, the U.S. must have a vibrant innovation culture and domestic manufacturing infrastructure scaled to national security needs. That culture and infrastructure must be a focus of continuous growth and investment, as any advantages in military technology will be fleeting. A pipeline of innovations, derived from a world-leading commitment to basic and applied research is essential for continued military preparedness. This also requires a world-class workforce and agile industrial sector that can quickly translate research results into new products and produce them at scale.

More on this topic: Navy Sails Into Supply Chain with Metal 3D Printing

These attributes align well with the strategic objectives addressing domestic supply chain capabilities identified in Strategy for American Leadership in Advanced Manufacturing, a report published by the National Science and Technology Council. It should be noted that any nation that makes such investments in its domestic manufacturing sector improves its national security position as well. Indeed, products and services that have emerged from federally funded research, including military projects, include GPS, modern smartphone technologies, computer numerical control machine tools, additive manufacturing, polymer and ceramic matrix composites, and countless more.

Technology Readiness

Research and development can be a somewhat nebulous term. Some government agencies differentiate between basic research, applied research, and development or design efforts. To better reflect some of the different activities within these catch-all terms, the DOD uses a more detailed approach, using nine technology readiness levels (TRL) and manufacturing readiness levels (MRL) to guide its planning and investment in new technologies—roughly, TRL 1-3 for basic research, 4-7 for applied, and 8-9 for development/design.

The differences between basic and applied research are worth unpacking.

Basic research is conducted for the purpose of advancing scientific knowledge. Though it often does not have immediate commercial objectives, successful basic research can reap a high payoff as it can introduce new science that can revolutionize old methodologies. But it also entails long lead times, high cost, and high risk; even when successful it may not be immediately translated into practice. Because of this uncertainty and long lead time, basic research in the U.S. is predominantly funded by the federal government.

Often, basic research is thought of in reference to space exploration or high-energy physics, but it can also fund small projects that can grow, unexpectedly, into giants. Perhaps the most dramatic demonstration of the impact of basic research is a little-referenced National Science Foundation grant in the Digital Library Initiative program to Stanford University, which included funding for graduate students Larry Page and Sergey Brin; within three years, their research on ranking matching pages on the World Wide Web became the basis for the company they founded in a friend’s garage. In 1998, Page and Brin incorporated Google, Inc. (As an illustration of the value of basic research, the tax revenues stemming from Google, its employees, and the add on effects throughout the economy greatly exceed the cumulative expenditures of the National Science Foundation since its founding in 1950.)

Applied research is more directed. It seeks to solve a specific problem and often requires the same level of creativity and scientific discovery, but it focuses on technologies that enable translation of scientific knowledge to commercialization at scale. Often, new manufacturing approaches are needed and require investigation, product features are redesigned to facilitate manufacture, and significant knowledge and value is embedded into the product. Because many promising breakthroughs discovered in basic research fail to move out of this stage, it is commonly referred to as the “valley of death.”

Unlike basic research, applied research historically was conducted and funded by industry. However, many countries employ extensive programs to subsidize expenditures in applied manufacturing research. The Made in China 2025 and associated programs, investing at least $1.4 trillion over 10 years, has raised eyebrows for its ambition. However, the German federal and state governments, through the Fraunhofer program, provide $2 billion that is matched by another $1 billion in industry match in a public-private partnership. Started with U.S. Marshall Plan funding after World War II, the Fraunhofer program is widely considered the most successful long-term commitment to manufacturing investment in the world. Canada, South Korea, the United Kingdom, and other nations make similar investments. It has been often demonstrated that manufacturing is located near the scale-up and manufacturing research, in order to capture the acquired knowledge in production.

Frontiers of advanced manufacturing: Lakshmi Vendra Reviews AM’s Use in Oil and Gas

American industry has lacked this scale of funding and its leadership in manufacturing has seriously eroded during the past few decades. The Manufacturing USA program, which is similar in focus and aspirations to the Fraunhofer program, has invested only $1 billion—total—in federal funding since its inception in 2012.

Recognizing that military innovations often emerge from the commercial sector, the Department of Defense has been the largest funding source for Institutes in the Manufacturing USA program. Indeed, the technological focus of many of these institutes aligns with anticipated procurement needs, from advanced lightweight metal manufacturing to the industrial production of biological solutions for injured veterans. However, just as military applications arise from industry technologies, industry can exploit manufacturing research directed toward military applications. The result is an innovation ecosystem that is much larger and impactful than the government funding and which can have demonstrable value from both a national security and economic competitiveness standpoint.

Manufacturing Innovation

As the United States enters the third decade of the 21st century, its national security landscape is changing. To meet new challenges, a greater commitment is needed to an innovation pipeline and manufacturing capability that can provide new military capabilities (including logistics). Other nations invest far more than the United States in public-private partnerships in manufacturing, as well as in manufacturing and engineering-based research. If the United States continues to lag adversaries and competitor nations—and remains dependent on other countries for components produced via advanced manufacturing—it could discover that it is unable to maintain its military advantage in future conflicts.

Editor's Choice: Advancing Additive Manufacturing in Aerospace

Some steps that could be taken to shore up the U.S. position include expanding the Manufacturing USA program and (as proposed in the Endless Frontiers Act introduced in Congress in 2020) establishing a second branch to the National Science Foundation that focuses on translational R&D including manufacturing. This development would place a stronger focus on manufacturing innovation and is consistent with the investment priorities of other industrialized nations. The lack of consistent funding has been a drawback—industry cannot plan to partner with the federal government when long-term commitments are uncertain.

More ambitiously, the government could establish a holistic approach to federal funding of manufacturing R&D. Nurturing of public-private partnerships in translational research is practiced worldwide, and a consistent commitment to this investment is needed in the U.S. Such a new approach could span the continuum from basic to applied research, tracking the progression of technologies (through periodic road-mapping) to ensure successful transition to market. State and federal government investments could also expand manufacturing education and workforce development investments that span high schools through community and technical colleges to doctoral degree granting institutions, in order to ensure that the next generation of American manufacturing workforce is trained using state-of-the-art infrastructure. (The potential demand by industry for skilled manufacturing workers is currently anticipated to outstrip demand by 2 million by 2030.)

National security requires maintaining a world-class manufacturing sector and promoting a perpetual innovation culture in the United States. The battles of tomorrow are being won—or lost—in university and industrial research labs today.

Steven R. Schmid is the Belk-Woodward Distinguished Professor of Engineering at the University of North Carolina at Charlotte and an ASME Fellow. Schmid also is an associate editor of the Journal of Manufacturing Science and Engineering. Shreyes N. Melkote is also an ASME Fellow and holds the Morris M. Bryan Jr. Professorship in Mechanical Engineering at the Georgia Institute of Technology in Atlanta as well as serves as associate director of the Georgia Tech Manufacturing Institute. Both serve on the ASME Manufacturing Public Policy Task Team, where Schmid is the chair. The authors gratefully acknowledge the helpful comments of Robert S. (Scott) Frost, Distinguished Analyst, ANSER, in the preparation and review of this manuscript.