Engineers Remember the Making of the Lunar Module

Engineers Remember the Making of the Lunar Module

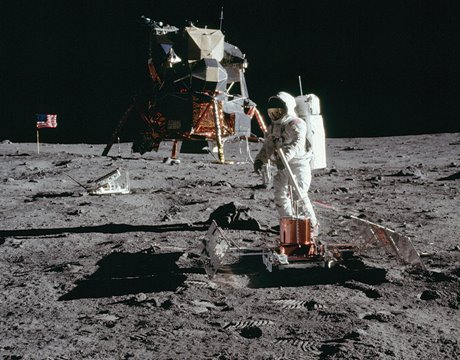

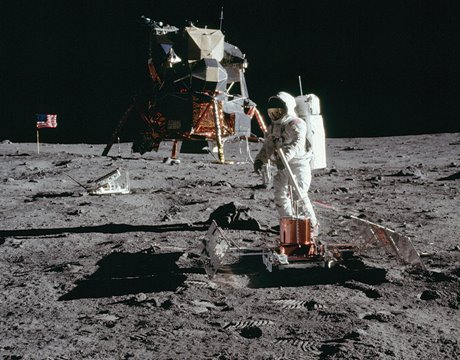

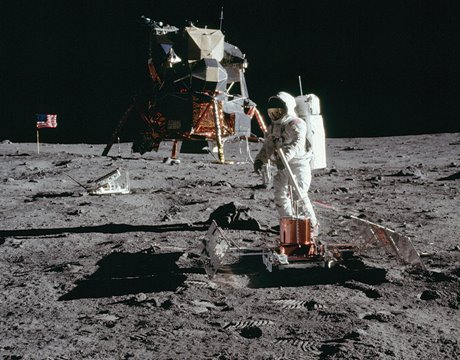

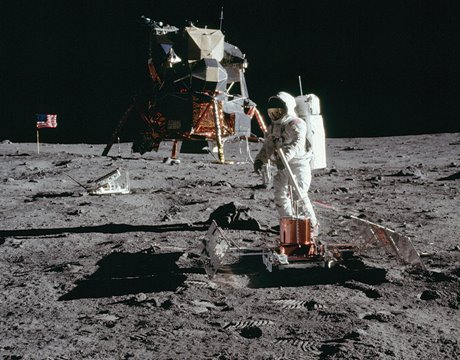

Buzz Aldrin sets up scientific equipment about 25 m from the Eagle. The lunar module was not only a pioneering spacecraft, it was designated a mechanical engineering landmark in 2002. Photo: NASA

The historical significance of Peter Kachmar’s job at the MIT Instrumentation Lab didn’t hit him until a few weeks after the bulk of it was finally over. It was a clear night toward the end of July when he took a minute to stare at the Moon. There are three men up there right now, he thought in wonderment, and two of them are actually on its surface.

“We put them there, and we returned them home safely,” he said to himself. “We did it.”

Kachmar was not only thinking of the country’s achievement, but also of the 400,000 engineers, technicians, and scientists who worked on the Apollo Program during the span of its 14-year run. Fifty years after Apollo 11 successfully put the first men on the Moon, engineers who worked on the mission say their feeling of pride, awe, and accomplishment are stronger than ever. Kachmar’s certainly is.

“When I was there working on it, it was more like, ‘We’ve got a job to do, we’re engineers, we can get the job done,’ ” said Kachmar, who joined the lab, now called Draper Laboratory, in 1965 and helped to develop the algorithms and crew procedures for the Apollo Rendezvous System, used to guide the lunar module from the command module to the moon’s surface, and back. “And I’ve come to realize what a tremendous feat it really was.”

Kachmar is not alone. On the 50th anniversary of Apollo 11, engineers across the country are reflecting on what turned out for many to be the most important, memorable, and influential job they’ve held throughout long and satisfying careers. Put into context, how couldn’t it be?

Read More about Top 10 Space Missions Set to Explore New Frontiers

Lunar Bound

Most of them were fresh out of school or signing on to their first real jobs. Within days of starting, they were creating new materials, technologies, structures, and spacecraft that would make the seemingly impossible dream of walking on the moon a reality. President Kennedy’s challenge “to go to the moon in this decade and do other things, not because they are easy, but because they are hard,” inspired and fueled them through long days and weeks.

Many worked alongside older engineers, stars in their fields, who dropped their egos to help a young colleague solve a problem and do the job right. They entered with the fundamentals of their education and left with a new set of knowledge, skills, and confidence that no school or other job could offer.

Galvanized, they all strove toward achieving a national goal–not one based on killing an enemy but on advancing humanity–that most of the world also embraced. And together, from the July 16 launch of the Saturn V rocket to the astronauts’ safe return on July 24, they celebrated the accomplishments that made Apollo 11 one giant leap for mankind.

“I cried and I cried,” said Anthony Cacioppo, remembering the Apollo 11 milestones he watched with his colleagues at the former Grumman Aircraft headquarters in Bethpage, N.Y. Cacioppo, a member of ASME’s Long Island section, worked from 1965 to 1970 as an intern at Grumman while studying for his engineering degree at Pratt Institute. “And … today … I still cry about that experience,” he said, unable to hold back the tears. “It was a wonderful experience.”

In 1962, the company beat out nine others for the sole contract to design and build the Apollo Lunar Excursion Module, later shortened to lunar module and typically referred to as the “lem.” Until the program ended, more than 3,000 engineers and 7,000 other Grumman employees hand-built 13 full versions of it.

For any engineer or technician, especially a young intern, the company was a special place to work, offering a goldmine of opportunity. “It was a gift, a privilege,” said Cacioppo, who worked on packaging new honeycomb sandwich materials, cable systems used to move the astronauts around during simulations, and instrumentation and environmental controls, among other areas.

Engineering Feat

The lunar module (LM) is still considered one of the world’s most important engineering achievements and remains the only crewed vehicle to land beyond the Earth. Designed for lunar orbit rendezvous, it sat directly beneath the command and service module (CSM) that rode atop the Saturn V rocket. Once parked in lunar orbit, the Apollo LM-5 Eagle, separated from the CSM and carried two astronauts, Neil Armstrong and Buzz Aldrin, to the Moon’s surface during the 24-hour landing mission that began shortly after 1 pm on July 20. A third astronaut, Michael Collins, remained in the CSM. After collecting soil samples and performing environmental tests, the astronauts flew the LM back to the CSM, where they re-boarded and discarded the module.

Overseen by Grumman aerospace engineer Thomas Kelly, almost every element of its design, construction, and testing pushed and expanded the limits of multiple engineering disciplines. The team developed and incorporated novel lightweight materials and cutting edge electrical, communication, navigation, and computer hardware and software systems.

Hear more about the Making of the Lunar Module on ASMETechCast

“As an engineer, you couldn’t want anything better than that. We were developing technology that had never been used before,” Cacioppo said at the Cradle of Aviation Museum in Garden City, N.Y., where he and other Grummanites recently met to reminisce about their experience. Several of those engineers volunteer as guides at the museum, which houses many exhibits based on the LM and includes one of the last built for the program. “Talk about an adventure. That’s part of the legacy that I look back on.”

In its heyday during World War II and the Cold War, Grumman’s aircraft and other products were so well built the company earned the nickname the Grumman Iron Works. The LM was no exception, proving to be one of the most consistently reliable of the Apollo mission vehicles. Ed Lee, a thermal engineer who helped forge the iron at Grumman, witnessed the LM’s reliability first-hand when in 1970 the crew of Apollo 13 reported, “Houston, we’ve had a problem.”

A Chinese immigrant, Lee took Kennedy’s space speeches to heart and pledged to help him send men to the Moon. “I thought, ‘This country is good to me. I have to do my best because of (Kennedy’s) challenge. I want to do something for my country,’” he said.

Lee had spent two years in ROTC and toyed with joining the Army. But his advisors thought his skills could be put to better use. “Because of my mechanical engineering (background), they said to do it the other way: ‘Instead of going to the front and fight for the country, you can do that with your knowledge of systems and engineering.’ And that’s what I did.”

Lee worked on developing the module’s external and internal insulation, environmental controls, and heat transfer systems needed to protect the astronauts and instruments from the extreme temperatures on the moon’s surface and the heat generated by the vehicle’s engines.

The major challenge was trying to keep the LM as light as possible. Like other engineers working on different elements of the program, Lee and his colleagues tested and re-tested everything they designed and implemented until there was no question about its reliability. That work was put to test toward the end of May 1969 during the Apollo 10 manned mission to orbit the moon, a dry run for Apollo 11. An operational mistake by the astronauts almost caused the LM to crash on the moon’s surface, but the module itself performed flawlessly. “That proved that this system we designed is working, and so we had confidence in the Apollo 11,” Lee said.

The LM’s success didn’t surprise Mike Lisa, who now leads the Cradle of Aviation’s volunteer program, given the amount of QA tests it underwent. Lisa signed onto Grumman in 1963 as an instrumentation engineer, a job that “became so varied it was pathetic,” he joked. His main duties, though, involved countless rounds of vibration, shock, and thermal vacuum tests to ensure the LM’s different components could withstand the rigors of space travel. “Every part had to be tested,” he said. “We knew what we had to achieve, and once we achieved that we had to go beyond it.”

Ross Bracco often went beyond. He worked on the LM mainly as a structural designer, as well as with the propulsion engineering group and the flight test department. One of his jobs was to design a panel to support tool components in one of the module’s high-vibration areas. He decided an extremely thin but strong honeycomb structure would work best. While all of the module’s components were designed to meet NASA’s criteria, the Grumman engineers would often add on safety factors of 15, 20, or 30 percent. Bracco tried to hit 100 percent on his. “I said, I don’t want my design to hurt anybody. I want to make sure these fellows had the opportunity to come home safely. So I designed a much higher safety factor on my own.”

Despite the confidence built through those redundancies and extra steps, the design teams still got nervous when NASA’s QA inspectors visited Bethpage. They never knew what to expect.

One day, the inspectors were examining the “clean room” where much of the LM was assembled. All of a sudden they announced they were shutting things down and made everyone leave the room. It turned out an inspector had found a discarded piece of chewing gum on the floor of the LM. “What precipitated was this incredible inspection that locked down production for almost a week,” Lisa said.

That type of QA, though, helped save lives of the Apollo 13 crew when a spark from an exposed wire in the

Odyssey CSM caused an oxygen tank to explode, shutting off power to it. The crew squeezed into the Aquarius LM, built for only two people and not designed for re-entry, using it for life support and propulsion.

Lee had just gotten home after a 12-hour shift working in mission support area and was watching TV when his boss called. “We have a problem,” he told Lee. “Get back here.” Lee went back and with his team consulted on how to reduce the power usage of the Aquarius and monitor the temperatures inside of it to get the astronauts safely back to earth. “We were able to do that,” he said.

Lee, along with Philip Jacknis, a 44-year ASME member and past chair of the Long Island section, served on the society’s nominating committee that designated the LM a national historic mechanical engineering landmark in 2002.

“It really was an iconic engineering feat,” said Jacknis, who had worked at Grumman for three summers beginning in 1966, keeping track of and distributing technical documents while studying mechanical engineering at The Cooper Union. He worked at the company for 44 years. “It underscores the saying ‘form follows function’ … it led to a very creative design.”

One Giant Leap

Harry Armen, past president of ASME, remembers the spirit of cooperation that fueled that creative, can-do engineering spirit that gave life to the entire Apollo program. He calls the time “the golden age of engineering,” with the LM as one of its crown jewels.

He started at Grumman as an intern in the summer of 1962 and retired as the company’s chief technologist 42 years later. During the Apollo program, Armen worked in the research department where he provided answers and solutions related to finite structural analysis, soil mechanics, aerodynamics, all types of optimization techniques, and shell theory for thin-walled construction, to name a few.

“It just went on and on,” he said. The engineers also relied on new mainframe computers and punch cards to solve large-scale equations simultaneously and quickly. “That was a remarkable development,” he said.

But Armen and other engineers across the country had access to something more remarkable than high-speed computers: engineering talent.

“Anywhere you looked in the company you could find someone who would help you. Experts came of the woodwork. There wasn’t a technical question you couldn’t get an answer for. People would drop what they were doing to solve your problem,” Armen said. “There was so much excitement at Grumman, the juices were flowing. ”

Frank Moskal, a mechanical engineer who focused on machine design and stress analysis after graduating from the University of Southern California in Los Angeles, experienced the same cooperation and solidarity across the country at North American Aviation in Downey, Calif., where the CSM and Saturn V’s second stage were built.

“I felt very inadequate because USC taught theory, not practical things. But the people I worked with were so good. Almost everyone had a specialty,” he said. “It was a great experience because you learned so much from the mature engineers.”

Many of the engineers working on the program faced similar situations as the young engineers today who must develop cross-disciplinary skills to perform jobs transformed by new technologies.

Moskal found himself working with cutting-edge technologies and systems that veered greatly from his core training. He learned computer skills, statistical analysis, and computerized welding. He worked with printed circuitry, early CAD systems, and resistive inks.

“The government was investing in its scientific talent at that time. It was sort of like a national treasure,” he said. “You felt like you were heavily valued.”

That feeling prevailed until the Apollo program ended, and tens of thousands of engineers were laid off. “It was awful,” Armen said. “One day you were working on the LM and the next day you were selling hotdogs on the street.”

Despite long hours, tremendous stress, and painful layoffs, something far greater remained for everyone involved. And that’s something engineers around the world will remember 50 years from now.

“The idea of sending someone to the Moon was something we all dreamed about ever since the first time anyone looked up and saw it in the sky,” Armen said. “You were part of that. It was the pride in doing something noble.”