9 Material Discoveries that Could Transform Manufacturing

9 Material Discoveries that Could Transform Manufacturing

Scientists continue to invent advanced materials with highly specific properties that outperform existing materials and enable more innovative product designs.

Manufacturing companies prefer to use tried-and-true materials for their products—these materials are already validated and their chemical and mechanical properties well-studied. However, product performance and functionality can often be improved with new materials that, once tested and approved, deliver highly specific engineered properties that enhance product performance and create product design options that were not available before. Below are some innovative materials that could transform manufacturing in the not-too-distant future.

Skoltech Center for Energy Science and Technology researchers in Moscow have created a titanium fluoride phosphate material to serve as a new cathode material. Its strong electrochemical potential and stability at high charge/discharge currents outperform the standard cathode materials of lithium and cobalt, which are expensive and of diminished supply.

The KTH Royal Institute of Technology in Sweden has developed a super-strong, biodegradable material using cellulose nanofibers from wood. The unique nanostructure of the material provides a tensile stiffness of 86 gigapascals and a tensile strength of 1.57 gigapascals—eight times stiffer than spider silk, considered the strongest biomaterial, and stronger than steel on a weight basis. This lightweight material could be an eco-friendly substitute for plastic.

Take Our Quiz: How Well Do You Know Your 3D Printing Materials?

A gel material made from aminopropyl methacrylamide (APMA) polymer, glucose, glucose oxidase, and chloroplasts continuously reacts with carbon dioxide from the air to expand and become stronger over time. It is the first carbon-fixing material to exist outside of biological beings. “Making a material that can access the abundant carbon all around us is a significant opportunity for materials science,” said lead researcher Michael Strano, professor of chemical engineering at MIT.

Researchers at Sandia National Laboratories have created a gold-platinum alloy that is 100 times more abrasion resistant than high-strength steel, even at high temperatures. The material’s excellent thermal stability is achieved by changing the grain boundary energies. Under stress, the alloy produces its own diamond-like carbon, which can act as a lubricant.

Composite metal foams (CMF) consist of hollow, metallic spheres, made from materials such as steel or titanium, which are embedded in a metallic matrix, typically made from steel or aluminum. Testing has shown that "steel-steel" CMF, so-called because both the spheres and matrix are made of steel, is much more fire-resistant than a solid steel plate. In addition, the steel-steel CMF panel is only one-third the weight of the solid steel plate. Therefore, CMFs are considered to be a promising material for protecting heat-sensitive materials during transportation and storage, such as explosives.

You May Also Like: 8 Ways 3D Printing is Helping to Fight Coronavirus

Spider silk is already regarded as one of the strongest materials in the world. Now scientists have discovered another unique mechanical feature: above a certain level of humidity in the air, the spider silk fibers suddenly contract and twist. This process—called super-contraction—exerts enough torsional force to possibly compete with other materials for use as actuators or other types of control devices.

Inspired by insect exoskeletons, researchers at Harvard University’s Wyss Institute for Biologically Inspired Engineering have created “shrilk,” a biodegradable “plastic.” Composed of chitosan, a component in shrimp shells, and a silk protein called fibroin, shrilk is as strong as aluminum and 50 percent lighter. Its biocompatibility, flexibility, and strength make it an attractive material for implantable medical devices and tissue engineering.

Researchers are studying how to reinforce concrete with carbon fiber to enhance strength and durability. A big advantage of carbon is that it does not oxidize. In contrast to steel-reinforced concrete, which can rust and degrade the structure, no thick concrete layers are required to protect the carbon. Adding carbon to concrete increases its loadbearing capacity by five or six times compared to traditional steel-reinforced concrete, is four times lighter, and has a significantly longer service life.

This synthetic porous ultralight material is 99.8 percent empty space. The end product of the supercritical drying of liquid gels, such as alumina, chromia, tin oxide, or carbon, the material is strong enough to carry 20,000 times its own weight. Aerogels are open-porous (the gas in the aerogel is not trapped inside solid pockets) and have pores in the range of <1 to 100 nanometers in diameter. The extremely low thermal conductivity also makes it a highly effective insulation material.

Editors' Pick: Biotechnology Anticipates 4D Printing

Scientists continue to make better materials that are stronger, lighter, and more functional than conventional materials. With advances in nanotechnology, new materials and material combinations seem endless. Current R&D includes studying rare earth elements, which have unique properties. For example, neodymium magnets can store impressive amounts of magnetic energy, making them ideal for turning rotors in wind turbines. Another rare earth element, cerium, when added to aluminum, improves its high-temperature performance. Cerium-aluminum alloys also have superior corrosion properties when compared to most aluminum alloys.

As Industry 4.0, the Internet of Things, and nanotechnology take center stage, engineers, scientists, and other researchers will continue to push the limits of material science. Not only will material advances improve what types of products we can manufacture, they will also enhance our chances to create a healthier and more sustainable world.

Mark Crawford is a technology writer based in Corrales, N.M.

1. Titanium Fluoride Phosphate

Skoltech Center for Energy Science and Technology researchers in Moscow have created a titanium fluoride phosphate material to serve as a new cathode material. Its strong electrochemical potential and stability at high charge/discharge currents outperform the standard cathode materials of lithium and cobalt, which are expensive and of diminished supply.

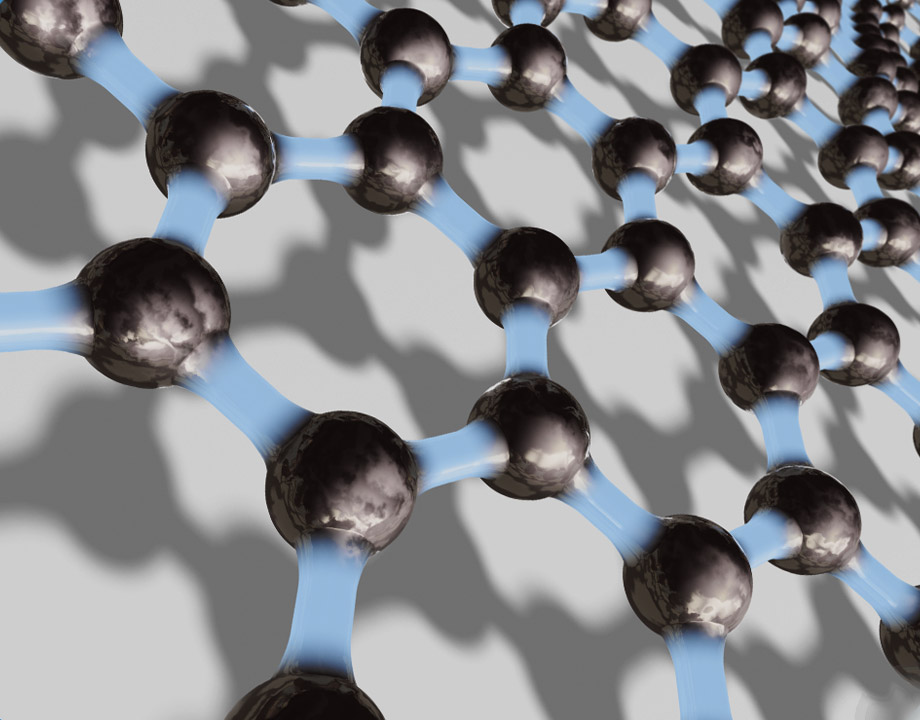

2. Cellulose Nanofibers

The KTH Royal Institute of Technology in Sweden has developed a super-strong, biodegradable material using cellulose nanofibers from wood. The unique nanostructure of the material provides a tensile stiffness of 86 gigapascals and a tensile strength of 1.57 gigapascals—eight times stiffer than spider silk, considered the strongest biomaterial, and stronger than steel on a weight basis. This lightweight material could be an eco-friendly substitute for plastic.

Take Our Quiz: How Well Do You Know Your 3D Printing Materials?

3. Self-Healing Gel

A gel material made from aminopropyl methacrylamide (APMA) polymer, glucose, glucose oxidase, and chloroplasts continuously reacts with carbon dioxide from the air to expand and become stronger over time. It is the first carbon-fixing material to exist outside of biological beings. “Making a material that can access the abundant carbon all around us is a significant opportunity for materials science,” said lead researcher Michael Strano, professor of chemical engineering at MIT.

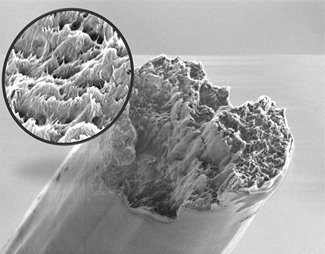

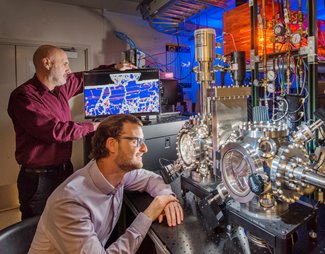

4. Platinum-Gold Alloy

Researchers at Sandia National Laboratories have created a gold-platinum alloy that is 100 times more abrasion resistant than high-strength steel, even at high temperatures. The material’s excellent thermal stability is achieved by changing the grain boundary energies. Under stress, the alloy produces its own diamond-like carbon, which can act as a lubricant.

5. Composite Metal Foams

Composite metal foams (CMF) consist of hollow, metallic spheres, made from materials such as steel or titanium, which are embedded in a metallic matrix, typically made from steel or aluminum. Testing has shown that "steel-steel" CMF, so-called because both the spheres and matrix are made of steel, is much more fire-resistant than a solid steel plate. In addition, the steel-steel CMF panel is only one-third the weight of the solid steel plate. Therefore, CMFs are considered to be a promising material for protecting heat-sensitive materials during transportation and storage, such as explosives.

You May Also Like: 8 Ways 3D Printing is Helping to Fight Coronavirus

6. Spider Silk

Spider silk is already regarded as one of the strongest materials in the world. Now scientists have discovered another unique mechanical feature: above a certain level of humidity in the air, the spider silk fibers suddenly contract and twist. This process—called super-contraction—exerts enough torsional force to possibly compete with other materials for use as actuators or other types of control devices.

7. Shrilk

Inspired by insect exoskeletons, researchers at Harvard University’s Wyss Institute for Biologically Inspired Engineering have created “shrilk,” a biodegradable “plastic.” Composed of chitosan, a component in shrimp shells, and a silk protein called fibroin, shrilk is as strong as aluminum and 50 percent lighter. Its biocompatibility, flexibility, and strength make it an attractive material for implantable medical devices and tissue engineering.

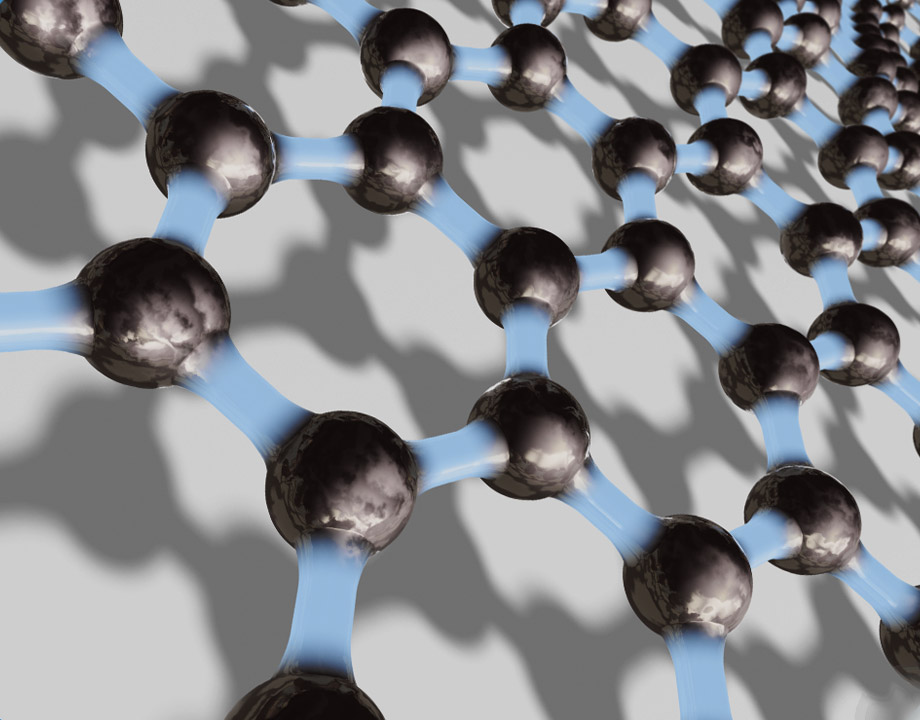

8. Carbon Concrete

Researchers are studying how to reinforce concrete with carbon fiber to enhance strength and durability. A big advantage of carbon is that it does not oxidize. In contrast to steel-reinforced concrete, which can rust and degrade the structure, no thick concrete layers are required to protect the carbon. Adding carbon to concrete increases its loadbearing capacity by five or six times compared to traditional steel-reinforced concrete, is four times lighter, and has a significantly longer service life.

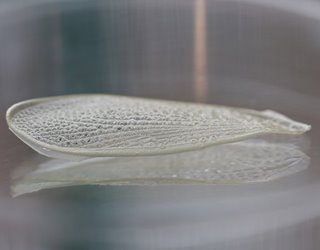

9. Aerogel

This synthetic porous ultralight material is 99.8 percent empty space. The end product of the supercritical drying of liquid gels, such as alumina, chromia, tin oxide, or carbon, the material is strong enough to carry 20,000 times its own weight. Aerogels are open-porous (the gas in the aerogel is not trapped inside solid pockets) and have pores in the range of <1 to 100 nanometers in diameter. The extremely low thermal conductivity also makes it a highly effective insulation material.

Editors' Pick: Biotechnology Anticipates 4D Printing

Materials for the Future

Scientists continue to make better materials that are stronger, lighter, and more functional than conventional materials. With advances in nanotechnology, new materials and material combinations seem endless. Current R&D includes studying rare earth elements, which have unique properties. For example, neodymium magnets can store impressive amounts of magnetic energy, making them ideal for turning rotors in wind turbines. Another rare earth element, cerium, when added to aluminum, improves its high-temperature performance. Cerium-aluminum alloys also have superior corrosion properties when compared to most aluminum alloys.

As Industry 4.0, the Internet of Things, and nanotechnology take center stage, engineers, scientists, and other researchers will continue to push the limits of material science. Not only will material advances improve what types of products we can manufacture, they will also enhance our chances to create a healthier and more sustainable world.

Mark Crawford is a technology writer based in Corrales, N.M.