3D Printing for Protection

3D Printing for Protection

This year's Emerging Tech Award winner Prusa Research’s open-source face shield design inspires makers to produce gear for healthcare workers. Illustration: Richard Borge

As the COVID-19 pandemic raged, healthcare workers were dealing with shortages of N95 masks, face shields, gloves, and other personal protective equipment (PPE) that they needed to keep from getting infected themselves. After seeing a number of projects trying to help frontline workers, Josef Průša decided to produce face shields with both 3D printed and laser-cut plastic components.

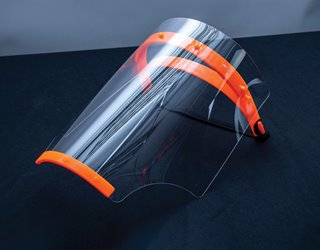

Průša could do this because he is the CEO and founder of Prusa Research, a Czechia-based 3D-printing startup. Leading the engineering team at his company, Průša designed, prototyped, verified, and began mass production of medical-appropriate face shields. Within three days, they had built dozens of prototypes that went through two verifications with the Czech Ministry of Health. He shared the company’s open-source design, which takes about an hour and twenty minutes to print, so anyone could download it for free and manufacture face shields using a 3D printer.

“What started as our local initiative to print protective face shields turned into a massive endeavor driven by 3D-printing communities worldwide. Tens of thousands of people began to print protective face shields using the design, helping hundreds of thousands of frontline staff—doctors, firefighters, police officers, social workers, and many other brave people who risk their lives every day in these difficult times,” Průša wrote in a blog post.

You May Also Like: Innovation in the Time of COVID-19

The design published on the company’s website became an important starting point for thousands of individuals and companies across the entire world. The design file of the 3D-printable face shield was downloaded 250,000 times.

The company also summarized its findings, precautions, and safety measures—including vital information about disinfection and certification—to inspire other makers who had access to 3D printers.

“During a time of crisis, many countries introduced emergency measures and allowed frontline staff to use uncertified PPE. However, that was an exception—the distribution of homemade PPE was more or less tolerated, depending on how bad the situation with official PPE was,” added Průša in the blog post. “From our experience, doctors were happy to receive any sort of help.”

However, the company still contacted the Czech Ministry of Health and received their official approval to manufacture and distribute face shields to medical, rescue, and social services.

Since March, the company has iterated the design to improve protection capabilities based on feedback from the users. The latest design called Prusa PRO Face Shield provides complete protection of the entire face and has passed the official certification, meeting the standard of EN 166:2001 for protection against drops and sprays (protection class 3).

Editors' Pick: 7 Manufacturing Lessons from COVID-19

In its effort to fight the coronavirus, the company has also produced and donated over 200,000 face shields to medics and other professionals in the Czech Republic.

“There’s so much good work being done and we’re incredibly proud of the entire 3D-printing community,” Průša wrote. “It’s an incredible collaborative effort that goes far beyond anything that 3D-printing communities have ever accomplished.”

Chitra Sethi is executive editor, media.

See who the other winners are in Video: 2020 Emerging Technology Awards

Register Today for the AM Industry Summit: Convergence of Aerospace & Energy