Aiming for a Better Vision with Multiphysics

Aiming for a Better Vision with Multiphysics

Case study provided by COMSOL

Presbyopia is a natural effect of aging in which a loss of elasticity in the lens of the eye causes far-sightedness. As a result, your visual accommodation gradually declines, as your eyes can no longer effectively change their optical power to maintain a clear image or focus on an object as its distance varies.

The current solutions to this problem are at opposite ends of the treatment spectrum: You can either wear a pair of glasses or opt for an invasive surgical solution that could compromise the quality of your vision.

A novel solution developed by medical device company Kejako will provide a viable treatment that treads the middle ground between surgery and spectacles. Their 3-D parametric full-eye model is providing invaluable insights into the root cause of the eye’s degeneration over time. As a result, Kejako is edging closer to an innovative solution that will delay the need for reading glasses or invasive surgery for over 20 years.

Personalized Treatment Options

“Our solution has the potential to become the next generation’s standard of care in personalized ophthalmic anti-aging medicine,” said David Enfrun, Kejako’s cofounder and CEO.

Kejako’s solution is designed to treat the root causes of presbyopia and features a series of noninvasive laser eye surgeries, which are prescribed from when a patient starts to develop presbyopia until cataracts develop. This keeps a patient’s visual accommodation amplitude above where spectacles are required.

To correct presbyopia, the team is combining the noninvasive treatment with simulation to provide an all-in-one solution called phakorestoration.

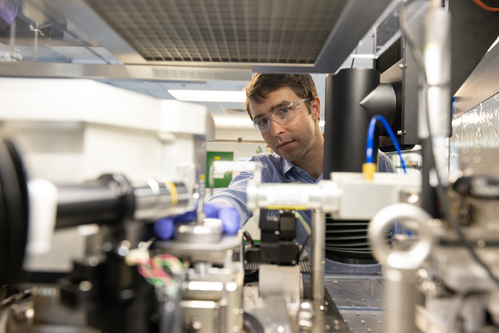

Their simulation work features a 3-D parametric full-eye model, which the company developed using multiphysics simulation. “In 2016 we started to work with COMSOL because of the multiphysics nature of the software and the high quality of customer support,” Enfrun said.

The full-eye model has the potential to provide a personalized treatment for every patient. This is important because every patient is different in terms of their physiology and the severity of their presbyopia.

Eyeing the Physics

To create an accurate 3-D parametric model of the eye, a full description of this organ must be taken into account and several physics phenomena be considered. “We needed a complete solution, including the mechanics and optics of the eye. We wanted to model the entire eye and adapt its properties to look at different outcomes,” said Aurélien Maurer, R&D engineer at Kejako and eye model project leader.

The team also wanted to model the gradient of the refractive index as light penetrates the crystalline lens, so they coupled structural mechanics and ray optics. “No one before had looked at the relation between the mechanical deformation and the refractive index gradient in the crystalline lens, so we decided to put this in a model and test it against the existing results in the literature,” said Maurer.

The team’s dual approach of modeling both the mechanical and optical elements of the eye was validated using existing measurements. “If we only model the mechanics or the optics, then we do not get all the information we need. But if we put all of this together, that’s where the magic happens,” Maurer added.

Multiphysics Focus

Using geometries from statistical measurements and standard optical coherence tomography imaging techniques, the team began to develop their model by imaging the eye and then translating this information into a parameterized 3-D geometry imported in the COMSOL software.

The mechanical elements of the eye were then modeled, including the complex muscle ligaments that pull the lens into shape and the viscoelastic properties of the vitreous fluid that fills the eye.

The fibrous nonhomogeneous nature of the sclera was also modeled. According to Charles-Olivier Zuber, a biomedical PhD student at Kejako and Rostock University, Germany, “The sclera is the white part of the eye and it is made of collagen fibers. Because those fibers are made of collagen, we needed to examine their nonlinear mechanical properties in a multiphysics environment.”

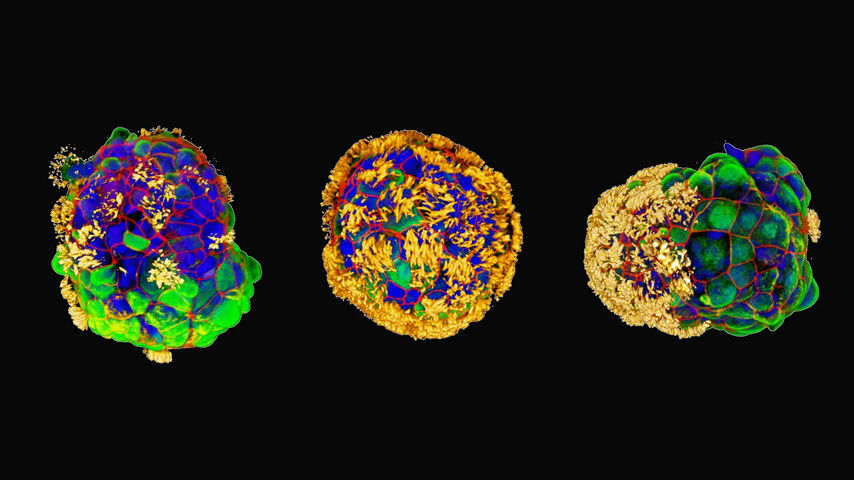

The ray optics capabilities of the software were used to trace the light rays, modeling the refractive properties of the lens and ray focusing on the retina, considering parallel incoming rays (as if they were emitted by an infinitely far source). This enabled simulations of the patient’s sharpness of vision and the objective amplitude of accommodation to be determined. Ray focusing of the eye optical system (cornea and crystalline lens) can be simulated.

The ability to model this vast range of parameters was key to the creation and success of the 3-D parametric full-eye model. “What we appreciate about COMSOL is that we have access to all of these parameters driving the geometric configuration, material properties, and physics involved. Such flexibility is very helpful to improve our comprehension of the problem and find the most effective solution,” said Zuber.

Give us a GRIN

Multiphysics simulation allowed the team to deduce some of the non-measurable mechanical properties of the lens, including the gradient of refractive index (GRIN) used in the 3-D parametric model of the eye. The refractive index of the human eye lens has subtle fluctuations and this creates a particular reflectance pattern.

The GRIN consists of spatial continuous variation of the refractive index over the lens, which increases from the surface to the center. This repartition has a strong influence on focalization of light, aberration, and thus visual acuity. Through simulation, the GRIN of the eye lens can be calculated, which is vital to understanding how light passes through the structure.

The GRIN value is incredibly difficult to measure directly, but its incorporation into the team’s parametric model was vital to ensure the accuracy of the model and, subsequently, the effectiveness of any proposed treatment.

Simulation for All

The team is now building simulation apps using the Application Builder available in the software to extend the reach of its 3-D parametric full-eye model and prepare the company for market maturity.

Once the multiphysics model is packaged into a simulation app with an easy-to-use interface, Kejako’s work is ready for a clinical setting through a straightforward process. A clinician can use standard OCT imaging to image the patient’s eye. This information is sent to Kejako, where the team of experts can create a personalized 3-D parametric full-eye model. This model is then further optimized and a customized phakorestoration procedure is created.

“Simulation and modeling have allowed for time savings with regards to our in vivo and ex vivo tests. We will move to trial when we are confident that we can do something significant in the human body and are convinced of our solution, and COMSOL Multiphysics will help us to achieve that in a much shorter time frame,” Enfrun added.

Read the original case study.

Learn more about the advances in modeling and simulation in Mechanical Engineering Magazine Special Report