Improving the Internal Combustion Engine, Part 1

Improving the Internal Combustion Engine, Part 1

The internal combustion engine may be a marvel of engineering, but that doesn’t mean it’s necessarily a modern one.

In fact, the basic design pioneered by Jean Lenoir in the 1850s isn’t too far off from the engine that is likely powering your car today. The idea of fuel ignited within a sealed engine block, with the force directed to cylinders and pistons that propel a vehicle, has been improved over the decades but remains largely the same today as it has always been.

And that’s part of the problem. There is only so much that engineers can do to improve the efficiency, performance, and durability of the time-tested internal combustion engine.

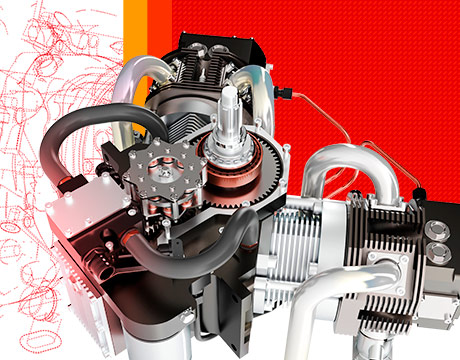

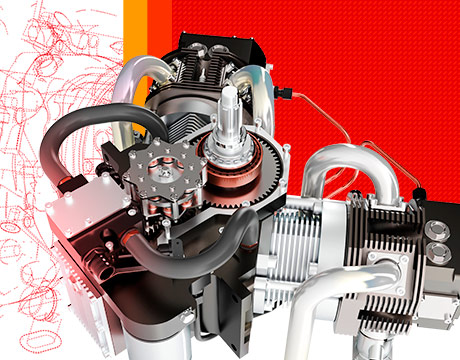

That’s why Amir Khajepour, a professor of mechanical and mechatronics engineering at the University of Waterloo in Waterloo, ON, Canada, and his team have been working on improving not the combustion chamber itself but the valves that control inputs and exhaust. Their innovation, a fully selectable system that can adjust the opening and closing of intake and exhaust valves, can increase the efficiency of internal combustion engines by more than 10 percent and is the result of more than a decade of work.

When we compared the initial valve timing to the optimal valve timing we realized that, by focusing the air that cuts into the piston, we can improve the overall power of the engine.Prof. Amir Khajepour, University of Waterloo

“Most new engines have a form of variable valve timing system (VVT), and there are many benefits to changing the timing of the valves when you are in different operation modes of the engine,” says Khajepour, whose research with the team focuses on developing cheaper, greener engines. You can access higher torque, or higher speed, or achieve better performance in other situations that the engine might be in.”

The problem is that the valves are typically cam controlled and cannot be freely adjusted. Most VVT systems can only be changed at set intervals. For example, they can only be switched between pre-established settings, or the user can only change both of them at the same time. In other words, the user cannot make changes to the opening and closing settings independently. That limits how much the engine can be fine-tuned.

What Khajepour has done is take this existing functionality and make it fully adjustable by replacing the cams with hydraulic cylinders and rotary hydraulic values. This will allow engineers to customize both the opening timing as well as the closing timing of the intake and exhaust valves to better dial in fuel efficiency, creating engines that are cheaper to fuel and release fewer carbon emissions.

“When we compared the initial valve timing to the optimal valve timing we realized that, by focusing the air that cuts into the piston, we can improve the overall power of the engine,” Khajepour says, explaining that the 10 percent efficiency gain figure may just be the beginning for this technology. “I'm sure that the efficiency could even be improved even more in a general drive cycle, because right now we are looking at the much wider operation [including stop-and-go-driving as well as highway driving], rather than just one operation.”

Find out in Part 2 How Khajepour and his team solved that problem.

Tim Sprinkle is an independent writer.

Read More on Design and Manufacturing:

Creative Approach to Engineering Improves Grades

Nanotechnology Fuels Safe Lithium Ion Batteries

Blockchain Could Change Face of Manufacturing