3D Systems’ First 3D Printer named Historic Mechanical Engineering Landmark by ASME

3D Systems’ First 3D Printer named Historic Mechanical Engineering Landmark by ASME

SLA-1 recognized for its transformational impact in engineering and manufacturing Landmark dedication ceremony held at 3D Systems headquarters, honoring Chuck Hull, inventor of 3D printing

NEW YORK, New York, May 18, 2016 – The American Society of Mechanical Engineers (ASME) announced today that it has designated SLA-1, the first commercial rapid prototyping system introduced by 3D Systems (NYSE:DDD), as a Historic Mechanical Engineering Landmark. SLA-1 was developed in 1987 from the work of Charles (Chuck) Hull, the inventor of Stereolithography (SLA) and Co-Founder and Chief Technology Officer of 3D Systems. ASME hosted a landmark dedication ceremony at 3D Systems’ headquarters in Rock Hill, SC, on May 18.

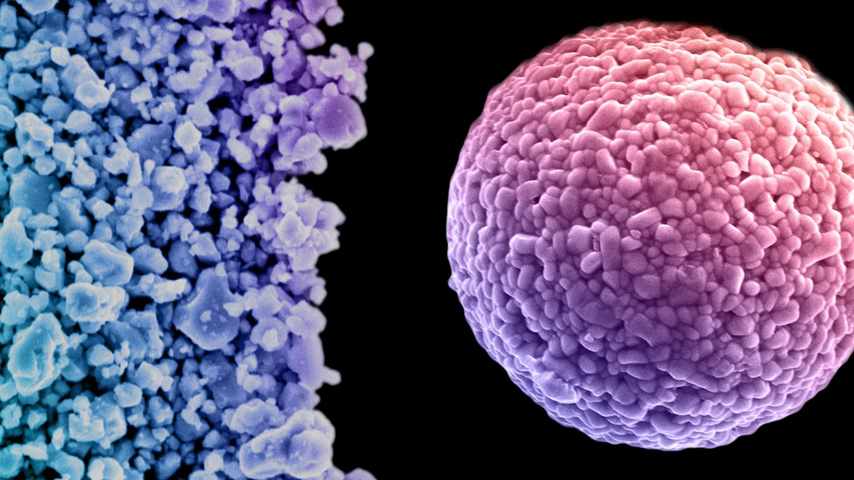

Hull invented SLA in 1983 as a rapid prototyping system that cures photopolymer resins layer-by-layer using UV lasers. Filed in 1984, the original SLA patent paved the way for new industries and new ways of thinking about design and manufacturing. Also known as ‘additive manufacturing’, 3D printing has been deemed a disruptive technology for its capability to displace established practices and introduce new opportunities in engineering and production. The SLA-1 joins over 260 ASME landmarks around the world.

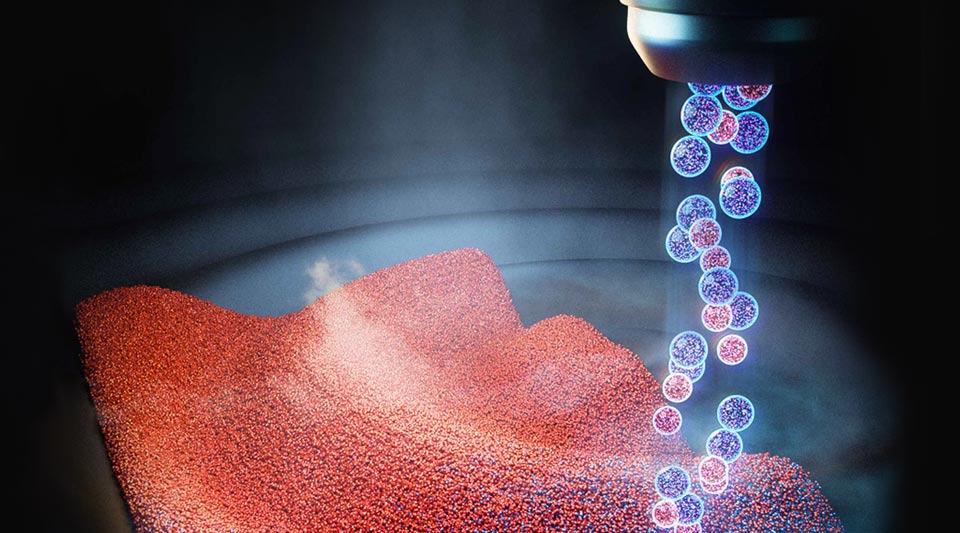

SLA-1 was invented as a means to shorten the manual prototyping and design verification processes that preceded it. By building parts one layer at a time, 3D printing has also become a way to produce complex geometries with improvements to functional efficiency and reduced material costs. Still the gold standard in accuracy, SLA capabilities have expanded to include more materials and configurations, including new technology showcased by 3D Systems, known as Figure 4, that is ultra-fast, modular, additive manufacturing designed for the automated manufacturing environment.

Watch this video to learn more about Figure 4 and the future of SLA.

“It’s a great honor for 3D Systems, and for me personally, to receive recognition by ASME for our original technology,” said Hull, Co-Founder and Chief Technology Officer, 3D Systems. “Although I expected 3D printing to be embraced by manufacturers, I never could have anticipated how widespread 3D printing is today, or the types of things that people are doing with it. For the past 30 years, we have had the distinct pleasure of watching our innovation spur more innovation, and we are excited to continue to shape the future.”

“The SLA-1 3D printer is a most deserving addition to ASME’s roster of mechanical engineering landmarks,” said ASME President Julio C. Guerrero. “SLA-1 is an integral piece of history in one of the world’s most promising technologies, and has profoundly influenced how we think and make.”

3D Systems and ASME celebrated the historical landmark designation of SLA-1 at 3D Systems Headquarters. A plaque is now on display next to the SLA-1 in the company’s lobby.

About ASME

ASME helps the global engineering community develop solutions to real world challenges. Founded in 1880 as the American Society of Mechanical Engineers, ASME is a not-for-profit professional organization that enables collaboration, knowledge sharing and skill development across all engineering disciplines, while promoting the vital role of the engineer in society. ASME codes and standards, publications, conferences, continuing education and professional development programs provide a foundation for advancing technical knowledge and a safer world. For more information visit www.asme.org

About 3D Systems

3D Systems provides comprehensive 3D products and services, including 3D printers, print materials, on demand manufacturing services and digital design tools. Its ecosystem supports advanced applications from the product design shop to the factory floor to the operating room. 3D Systems’ precision healthcare capabilities include simulation, Virtual Surgical Planning, and printing of medical and dentaldevices aswell as patient-specific surgical instruments.As the originator of 3D printing and a shaper of future 3D solutions, 3D Systems has spent its 30 year history enabling professionals and companies to optimize their designs, transform their workflows, bring innovative products to market and drive new business models.

More information on the company is available at www.3dsystems.com

ASME Media Contact:

Deborah Wetzel

Manager, Media Relations

wetzeld@asme.org

212.591.7085

3D Systems Media Contact:

Blaine Todfield

Senior Manager, Public Relations

blaine.todfield@3dsystems.com

803-322-7196