Researchers Destroy “Forever Chemicals” Using Supercritical Water

Researchers Destroy “Forever Chemicals” Using Supercritical Water

Researchers have created a reactor that uses “supercritical water” to break down dangerous "forever chemicals" into harmless byproducts.

“Forever chemicals” are highly stable compounds that persist in the environment for many decades. Because they do not break down, long-term exposure can impact human health. Two of the most prominent forever chemicals are perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), which have been in use since the 1940s. The International Agency for Research on Cancer and the U.S. Environmental Protection Agency have both warned that these chemicals are potential carcinogens.

To mitigate this serious environmental issue, researchers at the University of Washington, led by Igor Novosselov, research associate professor in the mechanical engineering department, have created a reactor that can break down these dangerous chemicals into harmless byproducts using “supercritical water” at high temperatures and pressures.

A supercritical fluid is any substance that is at a temperature and pressure above its critical point, where distinct liquid and gas phases cease to exist. This fluid has both gas and liquid properties and can be tuned to have more specific characteristics by changing the temperature and pressure.

“Our previous research has demonstrated that supercritical water oxidation [SCWO] can destroy recalcitrant chemical warfare agents,” said Novosselov. “When we heard about the ‘forever chemicals’ problem, we thought we had to try it. Cleaning up PFOA-PFOS contamination is a very important mission and we were excited to make a significant real-world impact, if our idea worked.”

Continue the Topic: Three Advances in Water Purification

PFOS and PFOA can be broken down in supercritical water at a very high rate. “If we get the conditions right, these recalcitrant molecules can be completely destroyed, leaving no intermediate products and yielding only harmless substances, such as carbon dioxide, water, and fluoride salts, which are often added to municipal water and toothpaste,” said Novosselov.

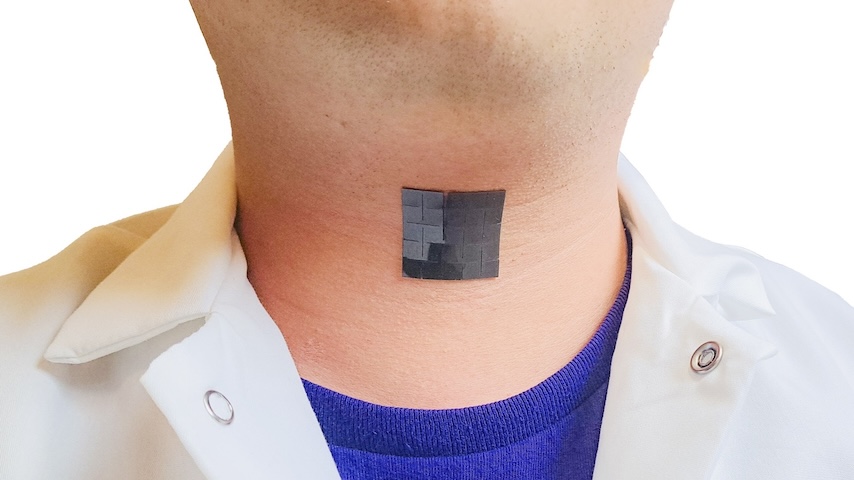

The core piece of Novosselov’s set up is the reactor.

“It is challenging to build a pressure vessel [250 atm] that can withstand high wall temperatures, so people stopped their research at 500-550 degrees C,” he added. “We built a reactor that co-fuels with alcohol or ethanol to bring the water temperature up to 650-700 degrees C while keeping the reactor walls within the material limits. This gave us a larger experimental envelope for determining what is required to oxidize these chemicals completely.”

Reactor design and construction required a multidisciplinary team of students and faculty.

Several interactions of the reactor were built. Team members learned from each other about fluid dynamics, chemical reactions, material properties, system controls, and various aspects of mechanical engineering. “It was like designing and building the first internal combustion engine or a gas turbine from scratch, then seeing that it starts and that you can use it in the car,” said Novosselov.

On A Related Note: Making A Greener Catalyst

The reactor consists of a thick, well-insulated, titanium-lined stainless steel pipe about a foot long and an inch in diameter. Temperatures inside the pipe can be adjusted to determine what temperature is needed to completely destroy a forever chemical. The SCWO reactor consisted of four influent streams: pilot fuel (ethanol-water mixture), air-water mixture, reagent-water mixture, and quench water injection port at the bottom of the reactor.

A pilot flame heated the water to supercritical condition. “At the top of the reactor, we continuously injected pilot fuel, air, and the chemical we wanted to destroy into the supercritical water inside the reactor,” said Novosselov. “The fuel provided the necessary heat for the mixture to remain supercritical, and the PFOS and PFOA rapidly mixed with this aggressive media. At the bottom of the reactor, the mixture is cooled down to yield both liquid and gas discharge. We can analyze what is in both the liquid and the gas phases to measure whether we’ve completely destroyed the chemical.”

Degree of disintegration varied according to temperature. PFOA broke down at mild supercritical conditions (around 400 °C); however, it required 610 °C and only 30 seconds to completely destroy the PFOS and all its intermediates.

Become an ASME Member: How To Join

“It still surprises me that we have operated the reactor for hundreds of hours and how robust the process continues to be,” said Novosselov. We have been running the reactor three to five days a week for the last year, with very little maintenance.”

Novosselov’s team is exploring how this process can be used to destroy a wide range of waste feedstocks, such as environmental, industrial, and legacy firefighting foams, for example.

Novosselov has applied for a patent and is interested in future commercialization. There are, however, a number of challenges in scaling up the system that need to be figured out. The team is also assessing how well this technology could work for real-world scenarios—for example, treating chemical waste at manufacturing sites.

“We are excited to be collaborating with regulators and leading groups in academia and industry to find the ultimate solution for breaking forever chemicals down into harmless, non-toxic components,” said Novosselov.

Mark Crawford is technology writer based in Corrales, N.M.

To mitigate this serious environmental issue, researchers at the University of Washington, led by Igor Novosselov, research associate professor in the mechanical engineering department, have created a reactor that can break down these dangerous chemicals into harmless byproducts using “supercritical water” at high temperatures and pressures.

A supercritical fluid is any substance that is at a temperature and pressure above its critical point, where distinct liquid and gas phases cease to exist. This fluid has both gas and liquid properties and can be tuned to have more specific characteristics by changing the temperature and pressure.

“Our previous research has demonstrated that supercritical water oxidation [SCWO] can destroy recalcitrant chemical warfare agents,” said Novosselov. “When we heard about the ‘forever chemicals’ problem, we thought we had to try it. Cleaning up PFOA-PFOS contamination is a very important mission and we were excited to make a significant real-world impact, if our idea worked.”

Continue the Topic: Three Advances in Water Purification

PFOS and PFOA can be broken down in supercritical water at a very high rate. “If we get the conditions right, these recalcitrant molecules can be completely destroyed, leaving no intermediate products and yielding only harmless substances, such as carbon dioxide, water, and fluoride salts, which are often added to municipal water and toothpaste,” said Novosselov.

The core piece of Novosselov’s set up is the reactor.

“It is challenging to build a pressure vessel [250 atm] that can withstand high wall temperatures, so people stopped their research at 500-550 degrees C,” he added. “We built a reactor that co-fuels with alcohol or ethanol to bring the water temperature up to 650-700 degrees C while keeping the reactor walls within the material limits. This gave us a larger experimental envelope for determining what is required to oxidize these chemicals completely.”

Reactor design and construction required a multidisciplinary team of students and faculty.

Several interactions of the reactor were built. Team members learned from each other about fluid dynamics, chemical reactions, material properties, system controls, and various aspects of mechanical engineering. “It was like designing and building the first internal combustion engine or a gas turbine from scratch, then seeing that it starts and that you can use it in the car,” said Novosselov.

On A Related Note: Making A Greener Catalyst

The reactor consists of a thick, well-insulated, titanium-lined stainless steel pipe about a foot long and an inch in diameter. Temperatures inside the pipe can be adjusted to determine what temperature is needed to completely destroy a forever chemical. The SCWO reactor consisted of four influent streams: pilot fuel (ethanol-water mixture), air-water mixture, reagent-water mixture, and quench water injection port at the bottom of the reactor.

A pilot flame heated the water to supercritical condition. “At the top of the reactor, we continuously injected pilot fuel, air, and the chemical we wanted to destroy into the supercritical water inside the reactor,” said Novosselov. “The fuel provided the necessary heat for the mixture to remain supercritical, and the PFOS and PFOA rapidly mixed with this aggressive media. At the bottom of the reactor, the mixture is cooled down to yield both liquid and gas discharge. We can analyze what is in both the liquid and the gas phases to measure whether we’ve completely destroyed the chemical.”

Degree of disintegration varied according to temperature. PFOA broke down at mild supercritical conditions (around 400 °C); however, it required 610 °C and only 30 seconds to completely destroy the PFOS and all its intermediates.

Become an ASME Member: How To Join

“It still surprises me that we have operated the reactor for hundreds of hours and how robust the process continues to be,” said Novosselov. We have been running the reactor three to five days a week for the last year, with very little maintenance.”

Novosselov’s team is exploring how this process can be used to destroy a wide range of waste feedstocks, such as environmental, industrial, and legacy firefighting foams, for example.

Novosselov has applied for a patent and is interested in future commercialization. There are, however, a number of challenges in scaling up the system that need to be figured out. The team is also assessing how well this technology could work for real-world scenarios—for example, treating chemical waste at manufacturing sites.

“We are excited to be collaborating with regulators and leading groups in academia and industry to find the ultimate solution for breaking forever chemicals down into harmless, non-toxic components,” said Novosselov.

Mark Crawford is technology writer based in Corrales, N.M.