Microstructures Improve Design and Function

Microstructures Improve Design and Function

How mechanical engineers work with microstructures is changing with computational micromechanics methods and codes.

Well, it depends.

The concepts of microstructure are covered in materials science and engineering courses, which can vary greatly in depth, depending on the focus of mechanical engineering undergraduate programs. For example, if a mechanical engineering program is focused on manufacturing, students will receive considerable exposure to microstructures.

Historically, MEs have viewed materials from the standpoint of their properties and associated mechanical behaviors, focusing on strength and failure models. Computational methods and design codes have been based on material models that may reflect microstructures in some way, but generally do not incorporate them directly.

However, “This paradigm is rapidly shifting as computational micromechanics methods and codes assist engineers in understanding what to focus on in control of material processing that gives rise to microstructures that improve performance,” said David McDowell, professor of mechanical engineering and materials science at Georgia Institute of Technology in Atlanta, Georgia. “This is an important aspect of Integrated Computational Materials Engineering (ICME), which brings mechanical engineering, process engineers, and materials scientists closer together in defining process routes and microstructures of materials that will meet design requirements in a reliable, sustainable way.”

Become a Member: How to Join ASME

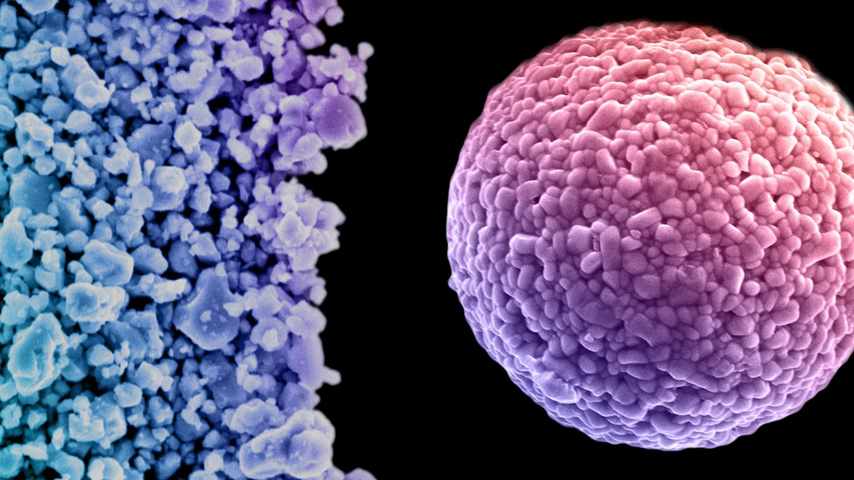

As a materials engineer, Mary Wells, dean of engineering at the University of Waterloo in Waterloo, Ontario, observed, “There is both an art and a science to examining, understanding, and evaluating microstructures and it can take years of time and effort to become proficient. Microstructures reveal their hidden structures that we cannot see with our naked eyes, which are both complex and beautiful.”

Microstructures and materials

In materials engineering, mechanical engineers study the properties of materials at the microscale to understand how they behave under different conditions and how they can be optimized for specific applications. This involves analyzing the microstructure of materials, such as their crystal structure, grain size, texture, and defects.

“We then take this information at the nano or micro scale and try and scale it up to predict how materials will behave at the macro scale,” said Wells. “Microstructures can be used to optimize the performance of mechanical systems such as airplanes by improving their strength, stiffness, and durability.”

Microstructure is especially important for engineers working in manufacturing settings such as automotive, aerospace, or materials processing. Microstructures are used to develop new processes for creating advanced materials with unique properties. For example, microelectromechanical systems (MEMS) are tiny mechanical devices that are fabricated using microstructures and are critical for applications such as sensors, actuators, and microfluidics.

In addition, “New technologies such as metal additive manufacturing require a detailed understanding of microstructure, which has caused some programs to revisit its importance in the formal training of undergraduate students,” said Matthew Daly, assistant professor in the Department of Civil, Materials, and Environmental Engineering at the University of Illinois in Chicago.

From an ASME perspective, activities within the Materials Division and the Applied Mechanics Division have become closely intertwined in how to improve the mechanics of materials approaches that predict microstructure-sensitive behavior of materials.

More for You: New 3D-Printing Process Uses Light to Make Complete Glass Microstructures

“This also involves imaging and digital characterization of microstructures, as well as numerical models for these complex fine-scale structures,” said McDowell. “So digital data science-enabled methods that exploit mechanics of materials and materials science are new, rapidly developing areas that have potential for enormous impact in discovery and development of new and improved materials in the coming decades. Computational mechanics of materials within mechanical engineering can only move forward by acknowledging the key role of microstructure, blending in 50 years of important developments in applied mechanics.”

Steady innovation

New tools, technologies, and software are moving microstructure design and analysis along quickly, partly because microstructure is defined by many parameters, making the design space incredibly vast. Also, developments in nanotechnology and additive manufacturing bring new ways to scale features and engineering microstructures. “The size of these features can vary widely, but they are generally on the order of micrometers to nanometers, with some structures even approaching the size of individual atoms,” said Wells.

Features can range from atomic level aspects such as composition of various atoms to point and line defects to grain and phase boundaries or interfaces. “We are moving towards digital characterization and storage of these microstructures as ‘fingerprints’ for each material,” said McDowell. “Innovations are needed in how to archive and extract these data, how to reconstruct material structure at various desired scales from them, how to simulate these data, and how to explore correlations between material structure at various scales and material properties or responses relevant to engineering applications.”

Editor’s Pick: New Metal Alloy Is Stronger than the Toughest Aerospace Materials

Advances in microscopy and imaging techniques have made it possible to visualize and analyze these tiny structures in more detail than ever before. The latest transmission electron microscopes and surface tunneling microscopes can image at the atomic scale.

“At intermediate scales,” said Anthony Rollett, US Steel Professor of Metallurgical Engineering and Materials Science at Carnegie Mellon University in Pittsburgh, “X-ray microscopy is rapidly becoming a reality. Lab-scale accelerators as X-ray sources would help democratize this. And microscopies continue to be developed, such as surface plasmon microscopy.”

One area of particular interest is the development of so-called metamaterials, which are artificial materials designed to have properties not found in nature. “These materials are created by arranging microstructures in specific patterns and configurations, and they have the potential to revolutionize fields such as optics, acoustics, and electronics,” said Wells.

Mark Crawford is a technology writer in Corrales, N.M.

This is the first of a two-part article exploring microstructures. Expect the second installment on May 30 on ASME.org.