Hybrid Cooling Could Cut Data Center Energy Use

Hybrid Cooling Could Cut Data Center Energy Use

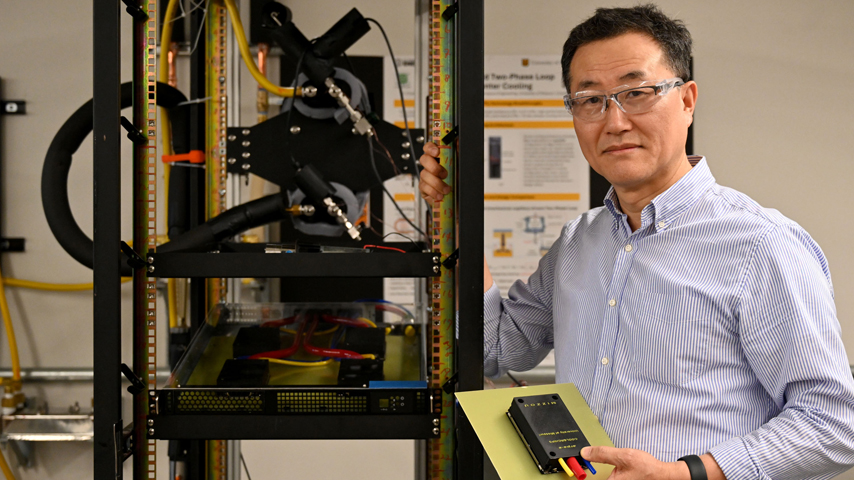

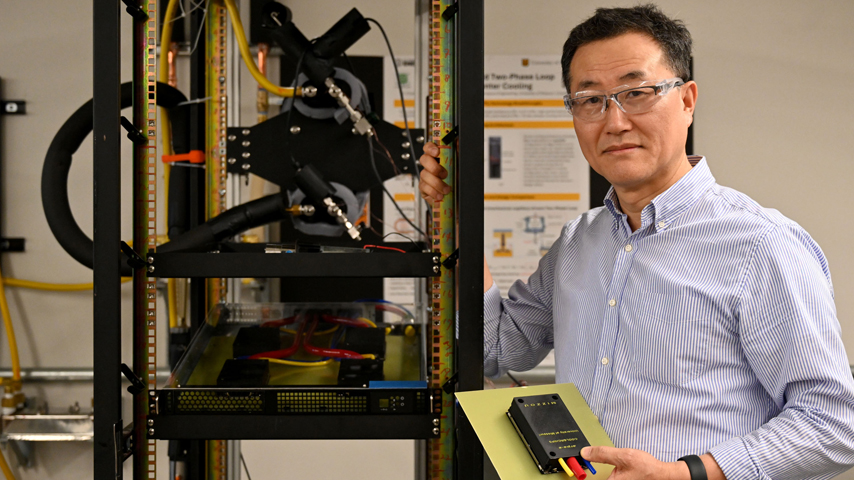

Chanwoo Park is developing a system that uses both capillary pumping with mechanical pumping to remove heat from computer data centers.

Demand for data center processing is soaring around the world, and that is putting pressure on electrical grids. Globally, data centers and their transmission networks each account for about 1-1.5 percent of global electricity use, according to the International Energy Association (IEA). In the U.S., the organization says the nation’s 2,700-plus data centers consumed more than 4 percent of the country’s total electricity in 2022, with cooling responsible for up to 40 percent of that load.

Energy demand from data centers will not abate any time soon. “We are in the middle of this AI age,” said Professor Chanwoo Park of the University of Missouri College of Engineering. Between artificial intelligence applications and bitcoin mining operations, data center energy consumption is expected to increase to 6 percent of total electricty by 2026.

“Currently, data centers are still one of the major energy consumers, but this consumption will be increasing significantly, probably many times,” Park said.

To look for new ideas for reducing data center energy demand, the U.S. Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E) awarded more than $40 million to 15 organizations. The grants were part of a program known as COOLERCHIPS, an acronym for Cooling Operations Optimized for Leaps in Energy, Reliability, and Carbon Hyperefficiency for Information Processing Systems.

The University of Missouri received nearly $1,650,000 in funding, which Park and his team are using to help develop a hybrid two-phase loop cooling solution intended for use in data center operations. The hybrid mechanical-capillary-drive, two-phase loop works both passively and actively, integrating capillary pumping with mechanical pumping.

“In terms of the design, it is quite robust, and the performance is quite impressive,” Park said.

The design is analogous to modern automobile technology that shuts the engine down when stopped at a red light, reducing fuel consumption, and which automatically turns on again upon acceleration—but applied to computers rather than cars. The two-phase loop system remains passive until activated by more demanding cooling conditions required by data center operations.

More on This Topic: Crunching Numbers, Sustainably

The capillary structure within the evaporator generates thin liquid layers that easily evaporate, dissipating heat from server chips with minimal thermal resistance, while the mechanical pumping enhances capacity by absorbing substantial amounts of heat. The proposed technology offers advantages over traditional data center cooling processes such as air-moving fans or liquid flows that move heat away from the computer racks, and which siphon enormous amounts of energy and water resources.

The technology is not new, having been developed over many years, and with each mode already demonstrated to work on its own, but the impact of successfully using them together is among the goals for the Mizzou team’s efforts.

In addition to the dual-mode operability, the technology also offers low thermal resistance, high heat flux, low pumping power consumption, high power density, reliable operation, and an opportunity to pursue future recycling of high-temperature heat exhaust.

Advances in Heat Transfer: Heat Transistor May Make for Cooler Computers

“This technology will produce high-grade heat, which is a high temperature heat. That's why this can be used to generate power,” Park said. “This is all possible because we have a very efficient heat transfer through a phase change.”

While the system offers scalability, it’s not without challenges, particularly when it comes to material fabrication and chip manufacturing. “It's not like a conventional manufacturing of material,” Park said. The process can be complex because it involves design of the material itself.

“We have to design the temporary structure, which is like a bit of porous material. It can be metallic material, or any other material,” Park explained. “We have to design this porous structure and then be able to fabricate those materials.”

“We have to design the temporary structure, which is like a bit of porous material. It can be metallic material, or any other material,” Park explained. “We have to design this porous structure and then be able to fabricate those materials.”

That process remains to be adopted on a commercial mass production scale.

“We are still finding the best way to manufacture, which involves a lot of problems to overcome,” Park said.

Park is optimistic that the many teams and organizations collaborating through the COOLERCHIPS program will lead to a commercially viable and mass-produced solution for use in high-end data centers. The partnerships offer a suite of expertise and equipment and other resources required for the effort to be successful, he said.

“We're talking about tons of power to operate these [data centers],” Park said.

Nancy Kristof is a technology writer in Denver, Colo.

Energy demand from data centers will not abate any time soon. “We are in the middle of this AI age,” said Professor Chanwoo Park of the University of Missouri College of Engineering. Between artificial intelligence applications and bitcoin mining operations, data center energy consumption is expected to increase to 6 percent of total electricty by 2026.

“Currently, data centers are still one of the major energy consumers, but this consumption will be increasing significantly, probably many times,” Park said.

To look for new ideas for reducing data center energy demand, the U.S. Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E) awarded more than $40 million to 15 organizations. The grants were part of a program known as COOLERCHIPS, an acronym for Cooling Operations Optimized for Leaps in Energy, Reliability, and Carbon Hyperefficiency for Information Processing Systems.

The University of Missouri received nearly $1,650,000 in funding, which Park and his team are using to help develop a hybrid two-phase loop cooling solution intended for use in data center operations. The hybrid mechanical-capillary-drive, two-phase loop works both passively and actively, integrating capillary pumping with mechanical pumping.

“In terms of the design, it is quite robust, and the performance is quite impressive,” Park said.

The design is analogous to modern automobile technology that shuts the engine down when stopped at a red light, reducing fuel consumption, and which automatically turns on again upon acceleration—but applied to computers rather than cars. The two-phase loop system remains passive until activated by more demanding cooling conditions required by data center operations.

More on This Topic: Crunching Numbers, Sustainably

The capillary structure within the evaporator generates thin liquid layers that easily evaporate, dissipating heat from server chips with minimal thermal resistance, while the mechanical pumping enhances capacity by absorbing substantial amounts of heat. The proposed technology offers advantages over traditional data center cooling processes such as air-moving fans or liquid flows that move heat away from the computer racks, and which siphon enormous amounts of energy and water resources.

The technology is not new, having been developed over many years, and with each mode already demonstrated to work on its own, but the impact of successfully using them together is among the goals for the Mizzou team’s efforts.

In addition to the dual-mode operability, the technology also offers low thermal resistance, high heat flux, low pumping power consumption, high power density, reliable operation, and an opportunity to pursue future recycling of high-temperature heat exhaust.

Advances in Heat Transfer: Heat Transistor May Make for Cooler Computers

“This technology will produce high-grade heat, which is a high temperature heat. That's why this can be used to generate power,” Park said. “This is all possible because we have a very efficient heat transfer through a phase change.”

While the system offers scalability, it’s not without challenges, particularly when it comes to material fabrication and chip manufacturing. “It's not like a conventional manufacturing of material,” Park said. The process can be complex because it involves design of the material itself.

Discover the Benefits

ASME Membership provides you an instant community of engineers, opportunities to stay on top of industry trends, and a host of other valuable benefits.

That process remains to be adopted on a commercial mass production scale.

“We are still finding the best way to manufacture, which involves a lot of problems to overcome,” Park said.

Park is optimistic that the many teams and organizations collaborating through the COOLERCHIPS program will lead to a commercially viable and mass-produced solution for use in high-end data centers. The partnerships offer a suite of expertise and equipment and other resources required for the effort to be successful, he said.

“We're talking about tons of power to operate these [data centers],” Park said.

Nancy Kristof is a technology writer in Denver, Colo.