7 Self-Healing Materials Expand the Limits of Engineering Design

7 Self-Healing Materials Expand the Limits of Engineering Design

Self-healing materials have a wide range of applications. The ability to self-heal extends product life.

Inspired by natural processes in the plant and animal world, such as protective or functional coatings, self-healing is accomplished in two ways: Autonomic, meaning no external stimuli are required to start the healing process; Non-autonomic, which does requires an external stimuli, usually through applying heat.

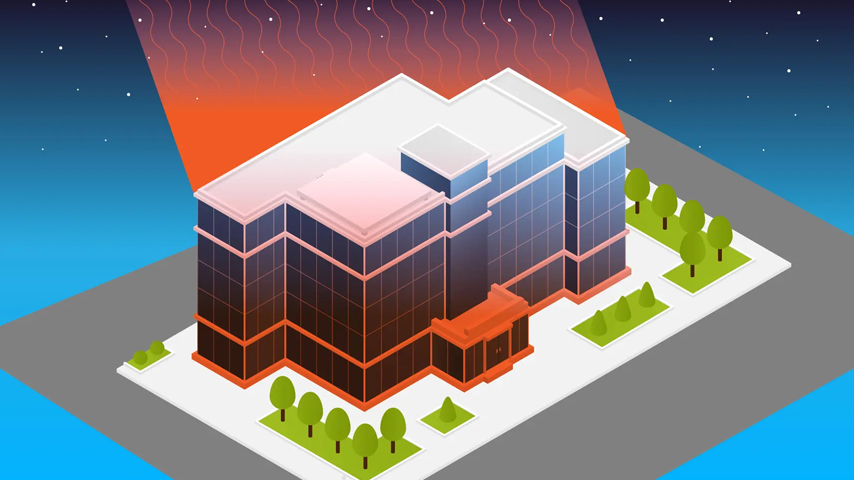

Self-healing materials have a wide range of applications, especially for critical infrastructure such as buildings, bridges, and dams and as a protective coating for steel and other materials that are exposed to corrosive environments. The ability to self-heal extends the longevity of products by fixing tiny structural failures before they become visible or even measurable problems.

Here are seven self-healing materials that will expand design options for engineers.

1. Hydrogels

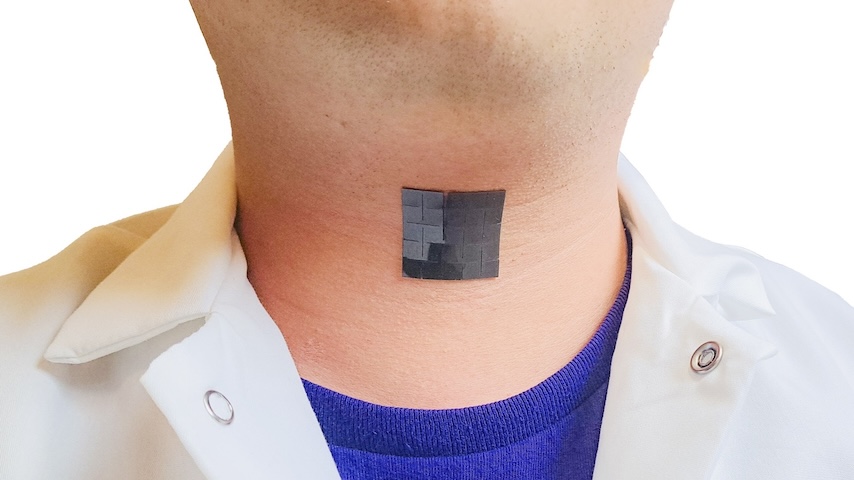

Self-healing polymer hydrogels rely on water to support reversible bonding that can promote healing. Hydrogels are firm like jelly and have elastic mechanical properties. The interaction between the hydrogel structure and electrostatic attraction forces stimulates the creation of new bonds, healing the site. Self-healing hydrogels have great potential for biomedical applications and robotics. For example, University of Cambridge researchers have developed a self-healing hydrogel that can help soft robots self-heal without the use of heat.2. Sulfur-Selenium Alloy

Rice University scientists have created a sulfur-selenium alloy that is flexible, insulating, and corrosion-resistant, making it a good choice for electronics, such as bendable cellphones. The material is also self-healing. The research team cut a piece of the material in half and placed the two pieces next to each other on a hotplate. Within 20 minutes at a temperature of 158 degrees Fahrenheit, the two pieces had reconnected. Possible applications include being a protective coating for steel.

3. Self-Healing Concrete

Researchers at Worcester Polytechnic Institute have invented a self-healing concrete that uses carbon dioxide to heal any cracks that develop. Inspired by how carbonic anhydrase (CA), an enzyme in red blood cells, can easily transfer carbon dioxide from the cells into the bloodstream, the team decided to add CA enzyme to the concrete mix. When cracks appeared in test products made from this mix, the enzyme reacted with carbon dioxide to form calcium carbonate crystals, sealing the fracture.

4. Self-Healing Carbon Fiber Composite

Carbon-fiber-reinforced composites are very popular for a variety of manufactured products. However, once damaged, these materials are nearly impossible to repair or recycle. Researchers have created a self-healing carbon fiber composite that can be repeatedly healed with heat, completely reversing any damage. The material is part of a material group known as carbon-fiber-reinforced vitrimers, which present both solid and fluid properties. It can also be recycled when it reaches the end of its life.

5. Aminopropyl Methacrylamide + Carbon Dioxide

Bioinspired from the process of photosynthesis, Massachusetts Institute of Technology researchers have developed a polymer that grows through a chemical reaction with carbon dioxide, thereby being able to fix any cracks that develop. The gel matrix is a combination of aminopropyl methacrylamide (APMA) and glucose. Chloroplasts catalyze the reaction of carbon dioxide to glucose, resulting in material growth and self-repair.

6. Self-Healing Ceramics

Although they are highly useful, a drawback to ceramic materials is that they are very fragile. A Texas A&M research team has developed a self-healing ceramic material based on chromium aluminum carbide. Its unique structure of alternating layers imparts the self-healing ability: When a crack begins, crystals form between and across the stressed layers, healing the crack. This could be a suitable material for products that operate in high-stress situations, such as aircraft engines.

7. Automobile Coating

A new coating for car surfaces can self-heal scratches in just 30 minutes. Developed by the Korea Research Institute of Chemical Technology, the transparent coating uses near-infrared light from sunlight to heal itself. The researchers created the material by adding a specific dynamic covalent bond to an existing commercial coating resin. Potential applications for the new material include being a protective coating on vehicles, electronics, and other devices that are routinely exposed to sunlight.

The variety of applications for self-healing materials will continue to expand as more of these unique materials are developed. They will make products and systems safer and longer-lasting and also expand the limits of engineering design.

“Self healing materials can be applied to build stronger bridges, skyscrapers, and other complex architectural achievements," wrote Chris Hristov, president of HH Consulting, a Las Vegas, Nev.-based structural engineering firm. “There are many uses for self-healing materials that go beyond structural engineering, but don’t underestimate their importance in improving structural safety, as well as increasing what is possible to achieve in the future as this technology advances.”

Mark Crawford is a science and technology writer in Corrales, N.M.